n any modern internal combustion engine, seals are provided to prevent oil from the cylinder head from entering the combustion chambers - oil deflector caps. Learn all about these parts, their types, design and principle of operation, as well as the correct selection and replacement of caps - learn from this article.

What is an oil deflector cap?

Oil deflector cap (oil scraper cap, valve seal, valve gland, valve sealing cuff) is a sealing element of the gas distribution mechanism of an internal combustion engine with overhead valves; A rubber cap mounted on the guide sleeve and valve stem to allow engine oil to enter the combustion chamber.

The valve mechanism located in the cylinder head creates a serious problem: the possibility of oil entering the combustion chambers from the top of the head. Oil seeps through the gaps between the valve stems and their guide sleeves, and it is almost impossible to eliminate these gaps. To solve this problem, special sealing elements are used - oil scraper (oil-deflecting) caps located on the top of the guide and sealing the gap between the valve stem and the guide.

Oil scraper caps perform two functions:

● Prevention of oil ingress into the combustion chambers of the cylinders when the valves are opened;

● Prevention of exhaust gases from the combustion chamber entering the gas distribution mechanism located on the head.

Thanks to the caps, the necessary composition of the combustible mixture in the combustion chambers is provided (oil does not get into it, which can disrupt the combustion mode of the mixture, lead to increased smoke and a decrease in the power characteristics of the engine), reduces the intensity of carbon deposits on the combustion chamber and valves (carbon deposits can lead to a deterioration in the density of valve closure) and prevents excessive contamination of engine oil. Faulty, worn-out caps immediately make themselves felt, they adversely affect the operation of the engine, therefore they must be replaced as soon as possible. But before you go to the store for new valve oil seals, you need to understand their existing types, designs and features.

The design of the oil scraper cap

Types and design of oil deflector caps

All gland valve seals used on modern engines can be divided into two types according to design and installation method:

● Cuff caps;

● Flange caps.

Parts of both types have a similar design, differing only in one detail and installation feature.

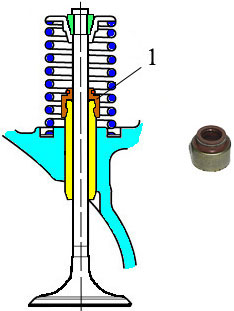

installation of the cuff type oil scraper cap

The design of the lip type cap is based on a variable diameter rubber sleeve, its lower part is made to match the diameter of the valve guide sleeve, and the upper part has the diameter of the valve stem. The cap is made of various types of rubber that are resistant to high thermal and mechanical loads, most often fluororubber. The inner surface of the cap - the surface of the fit to the guide - is corrugated to ensure the best contact and a snug fit. The surface of the valve stem is usually made in the form of a working edge with bevels that provide better oil removal from the stem when the valve moves downwards.

On the outer surface of the cap there is a reinforcing element - a steel stiffening ring, which ensures ease of operation when installing the oil seal and its reliable fit during engine operation. In the upper part (at the point of adhesion to the valve rod) on the cap there is a coil spring rolled into a ring - it provides tight contact of parts, preventing the penetration of oil and the breakthrough of exhaust gases from the combustion chamber.

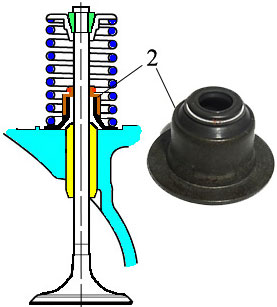

Structurally, flanged caps are similar to lip caps, with the exception of one detail: in these oil seals, the metal stiffening ring has an increased length, and in the lower part it passes into a flat flange of a larger diameter than the cap itself. When installing such a cap, the valve spring rests on its flange, ensuring a secure fit of the seal.

It should be noted that today there are also oil deflector caps of composite design. Their lower part is made of denser and heat-resistant rubber, and the upper part is made of more elastic rubber, which achieves high resistance of the part to various loads. The connection of parts is carried out by a metal ring of complex shape.

According to their purpose, oil scraper caps are divided into two types:

● For intake valves;

● For exhaust valves.

Since the intake and exhaust valves have different diameters on the same engine, the corresponding seals are also installed on them. For reliable identification and correct installation of the intake and exhaust valve caps, they have different colors.

Installation of flange-type oil scraper cap

As already indicated, the oil deflector caps are mounted directly on the valve guide sleeves and cover the valve stems with their upper part. The oil flowing down the valve stems is stopped by the working edge at the top of the cap, which prevents it from entering the combustion chamber. In the same way, the exhaust gases are retained on the reverse side (which is facilitated by the ring spring). The tightness of the working edge to the valve stem is ensured by both the elasticity of the rubber and the additional spring ring. The number of oil scraper caps in the engine corresponds to the number of valves installed on it.

How to choose and replace oil deflector caps correctly

Oil scraper caps are replaceable parts that must be replaced with new ones as they wear out. For different engines, different terms are set for routine replacement of caps - from 50 to 150,000 km. However, seals often wear out prematurely, the need to replace them is indicated by increased smoke of the exhaust, increased oil consumption, and in gasoline engines - also splashing candles with oil. This suggests that the working edges of the caps have already lost their elasticity and do not fit snugly to the valve stem, or the caps are simply cracked, deformed or destroyed.

Flanged oil scraper caps

For replacement, it is necessary to take the same oil scraper caps that were installed on the engine earlier. In some cases, other oil seals can be used, but it is very important that they fully comply with the original installation dimensions and material of manufacture (especially in terms of heat resistance), otherwise the caps will not fall into place and will not provide normal sealing.

Replacement of oil deflector caps must be carried out in accordance with the instructions for repair and maintenance of the car. Usually, this procedure boils down to the following:

1.Dismantle the cylinder head cover;

2.If necessary, dismantle camshafts, rocker arms and other parts of the timing drive that will interfere with work;

3.Turn the crankshaft of the engine so that the piston, on the valves of which the caps will change, stands at top dead center (TDC);

4.Drying the valves is a separate operation that is performed in accordance with its instructions. For drying, it is necessary to have a special device for compressing valve springs, a magnet for extracting crackers will also be useful;

5.After removing the springs, dismantle (press) the cap - it is best to use a special device with a collet grip, but you can simply use pliers or two screwdrivers, but here it is important not to damage the valve stem;

6.Take a new cap, lubricate its inner surface with oil and press it onto the sleeve using a special mandrel. You can first remove the spring from the cap and then put it on. It is extremely difficult to install a cap without a mandrel and almost always this leads to damage to the part;

7.Perform the specified operations for all caps and reassemble.

It is very important to use special devices to replace the oil deflector caps - an inertial puller and a mandrel for pressing. Otherwise, there is a very high risk of ruining all the work and spending extra money. After replacement, the caps do not require special care, it is only sometimes necessary to pay attention to their condition according to the peculiarities of the engine.

With the right choice and replacement of oil scraper caps, the oil in the cylinder head will not cause problems, and the operation of the engine will meet the standards.

Post time: Jul-26-2023