When repairing the clutch in cars with a manual transmission, it is difficult to center the driven disc. To solve this problem, special devices are used - mandrels. Read about what a clutch disc mandrel is, how it works and how to use it correctly in the article.

What is a clutch disc mandrel

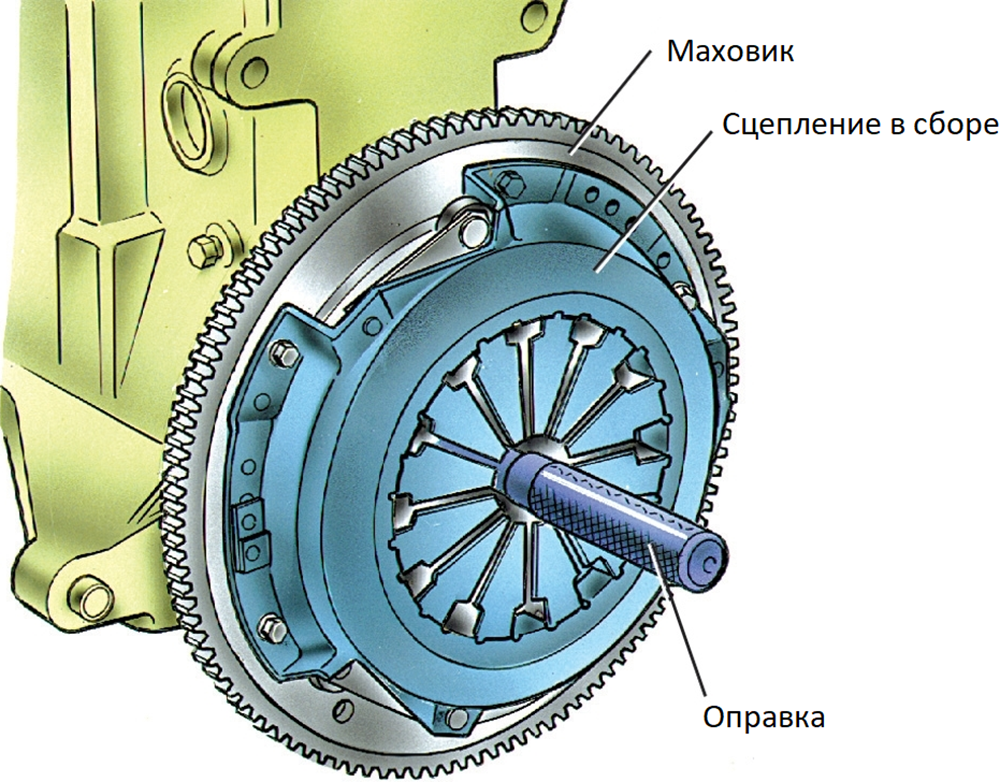

Clutch disc mandrel (clutch disc centerer) is a device for centering the driven disc relative to the flywheel and/or pressure plate when repairing a single-plate clutch in vehicles with a manual transmission.

Most vehicles with a manual transmission (manual transmission) are equipped with a dry friction clutch with a single driven disc. Structurally, this unit consists of a pressure plate located in a casing ("basket"), which is rigidly mounted on the engine flywheel. Between the pressure plate and the flywheel is a driven disc connected to the input shaft of the gearbox (gearbox). When the clutch (pedal released) is engaged, the pressure plate is pressed by springs against the driven disc and the flywheel, due to the frictional forces between these parts, the torque from the engine flywheel is transmitted to the input shaft of the box. When the clutch is disengaged, the pressure plate is removed from the slave, and the torque flow is broken - this is how the clutch works in general terms.

Clutch parts, especially the driven disc, are subject to intense wear, which requires periodic disassembly of this entire unit and replacement of its components. When assembling the clutch, some difficulties arise: the driven disc does not have a rigid connection with other parts before tightening the basket bolts, therefore it shifts relative to the longitudinal axis of the entire assembly, which makes it difficult or impossible to connect it to the input shaft of the gearbox. To avoid this problem, before assembling the clutch, it is necessary to center the driven disc, to perform this operation, a special device is used - the clutch disc mandrel.

The mandrel (or centerer) allows you to accurately install the driven disc and facilitate its docking with the input shaft of the gearbox, while saving time and effort. However, a positive result can only be achieved if the mandrel is precisely suited to the driven disc and the entire clutch. Therefore, before buying a mandrel, you should understand the existing types of these devices, their designs and application features.

Applying the

clutch disc mandrel Positioning the clutch disc with a universal mandrel

Types, design and features of clutch disc mandrels

In the role of the simplest mandrel for the correct assembly of the clutch, a segment of the input shaft of the gearbox can act. However, this option is not always available, and it is not convenient, so specially made mandrels are most widely used. These devices can be divided into two large groups according to their purpose:

● Special - for certain cars or clutch models;

● Universal - for various cars.

Centering mandrels of various types have their own design features and principle of operation.

Special clutch disc mandrels

Mandrel of this type is usually made in the form of a steel bar of variable profile, which can be divided into three sections:

● End section with a diameter corresponding to the diameter of the central sleeve or support bearing of the input shaft of the gearbox located in the flywheel;

● The central working part with a diameter corresponding to the diameter of the spline hole of the driven disc hub;

● Handle for holding the tool during operation.

In general, a special mandrel imitates the end part of the input shaft of the gearbox, but it is lighter and more convenient to use. Usually, the central working part of the mandrel is smooth, but you can find devices with a spline working part. A notch or other corrugation may be applied to the handle to prevent the hand from slipping.

Such a mandrel is installed by the end section in the central sleeve or in the bearing in the flywheel, and a driven disc is put on its working part - in this way the parts are lined up along the common axis. After mounting the clutch basket, the mandrel is removed, and its place is taken by the input shaft of the gearbox.

Special mandrels can have different functionality:

● Only for centering the clutch driven disc;

● With additional functionality - for the installation of oil scraper (oil-deflecting) engine valve caps.

The most common are conventional mandrels, and devices for centering discs and installing oil scraper caps are widely used for repair and maintenance of domestic cars VAZ "Classic" and some others. Such mandrels have an additional element - a longitudinal channel at the end, corresponding to the shape of the cap, with the help of which the caps are mounted on the valve stem.

Special mandrels are made of steel, but on the market you can also find devices made of various high-strength plastics.

Universal clutch disc mandrels

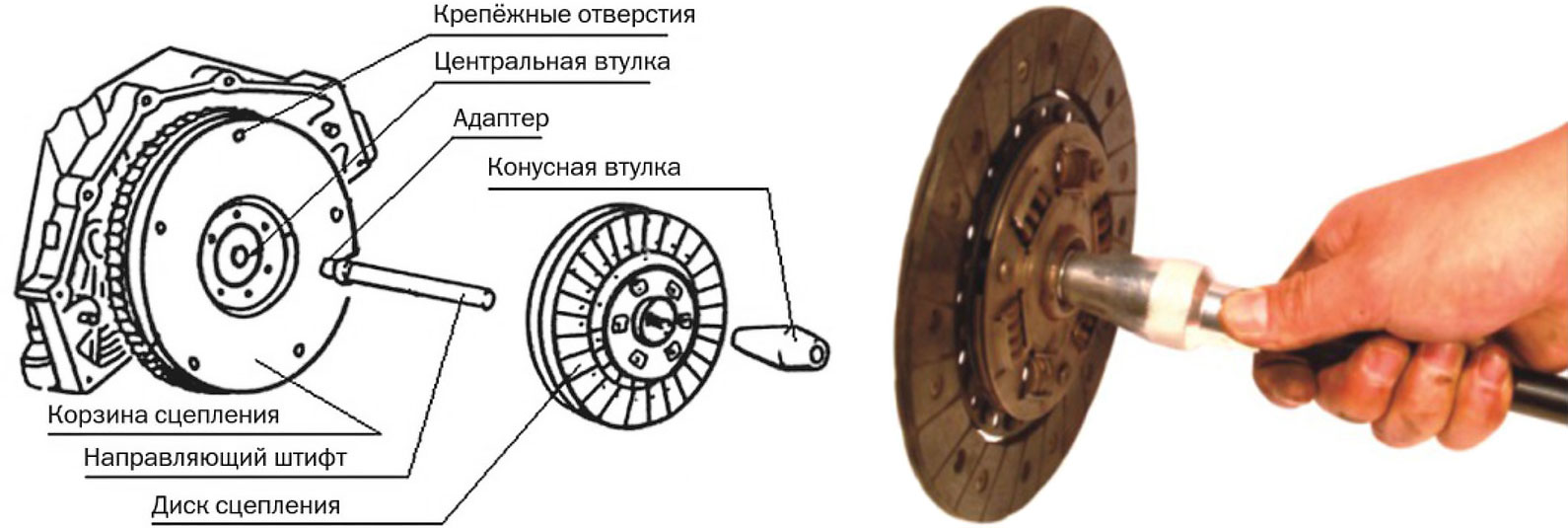

Such devices are made in the form of kits from which it is possible to assemble mandrels of the required diameter. There are three main structural types of mandrels:

- Collet with tapered sleeve;

- With interchangeable constant diameter adapters and tapered sleeve;

- Cam expanders with interchangeable adapters of constant diameter.

Collet mandrels are used to center the driven disc relative to the clutch pressure plate. The basis of the fixture is a steel rod with an extended tapered head and a thread on the opposite side. A plastic collet nozzle with an extension at the end and four longitudinal incisions is put on the rod. A plastic mandrel body is put on the nozzle, on which a large thread is applied and a wheel with a notch is provided. A plastic cone is screwed onto the body, and a plastic adjustment wheel is screwed onto the thread of the rod. This entire assembly is threaded into the hole in the clutch basket, the end of the nozzle is inserted into the hub of the clutch driven disc. By rotating the adjustment wheel, the rod is drawn into the nozzle, which, due to expansion on the rod, moves apart and jams in the disc hub. Then a cone is screwed in, which enters the hole in the basket (or pressure plate), due to which the parts are centered. The basket assembly with the mandrel is mounted on the flywheel, and after mounting the clutch, the mandrel is removed.

Mandrels, with interchangeable adapters and a tapered sleeve, ensure that the driven disc is centered relative to the flywheel. The fixture consists of a steel guide rod (pin) with a thread at the end, on which steel adapters of various diameters are screwed, and then a tapered sleeve is installed. The rod assembly with the adapter is installed in the center sleeve or support bearing in the center of the flywheel, then the clutch driven disc is put on the rod, and then the tapered sleeve. Due to the clamping of the cone included in the hub of the disc, the centering of the parts is ensured, after which the clutch basket can be installed.

Clutch

disc centering kit Universal clutch

disc mandrel Cam expansion mandrels clutch disc

Cam expansion mandrels also ensure that the driven disc is centered relative to the flywheel. Such a mandrel is made in the form of a rod with a threaded tip on which the adapter is installed. In the body of the mandrel there is an expansion mechanism with three cams and a drive from a screw located on the reverse end of the device. When the screw rotates, the cams can exit and enter the mandrel. For alignment, a device with an adapter of the required diameter is installed in the central sleeve or in the support bearing in the flywheel, then the clutch driven disc is installed on the rod and fixed with cams. Due to the uniform exit of the cams, the disc is centered with the flywheel, after which the clutch basket can be installed.

Today, there is a wide variety of universal mandrels for clutch driven discs with a hub bore diameter of 15 mm or more and with a center sleeve/support bearing diameter of 11 to 25 mm.

How to select and use the clutch disc mandrel

The choice of device must be made on the basis of its future use, frequency of use and characteristics of the vehicle. If you have to repair one car, then the best solution would be a special mandrel - it matches the clutch parts as closely as possible in size, is easy to use and reliable (since this is one steel or plastic part). To work with various cars, it makes sense to turn to universal nozzles - one set allows you to center the clutch discs on both cars and trucks, and sometimes on tractors and other equipment. At the same time, it should be borne in mind that collet mandrels do not require a support bearing or a central sleeve in the flywheel, and devices with interchangeable adapters and expansion ones cannot be used without a sleeve or bearing.

It is necessary to apply mandrels in accordance with the instructions for the repair and maintenance of vehicles. If all recommendations are followed, clutch repair will be carried out efficiently and quickly.

Post time: Jul-11-2023