Normal operation of the engine is possible only if its crankshaft does not have a significant axial displacement - backlash. The stable position of the shaft is provided by special parts - thrust half-rings. Read about crankshaft half-rings, their types, design, selection and replacement in this article.

What is a crankshaft support half-ring?

The oil pressure sensor is a sensitive element of instrumentation and alarm devices for the lubrication system of reciprocating internal combustion engines; A sensor for measuring the pressure in the lubrication system and signaling its decrease below a critical level.

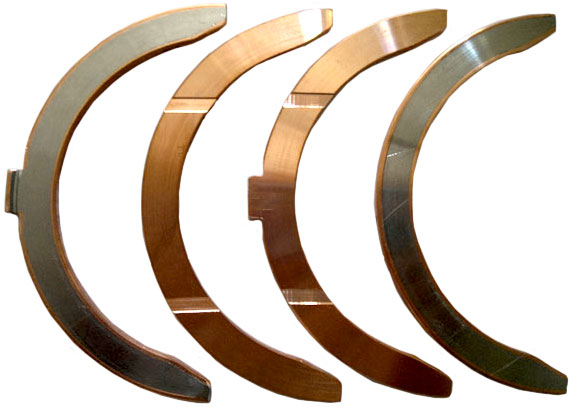

Crankshaft thrust half-rings (support half-rings, crankshaft washers, crankshaft thrust bearing half-rings) are special plain bearings in the form of half-rings that establish the working axial displacement (backlash, clearance) of the crankshaft of an internal combustion engine.

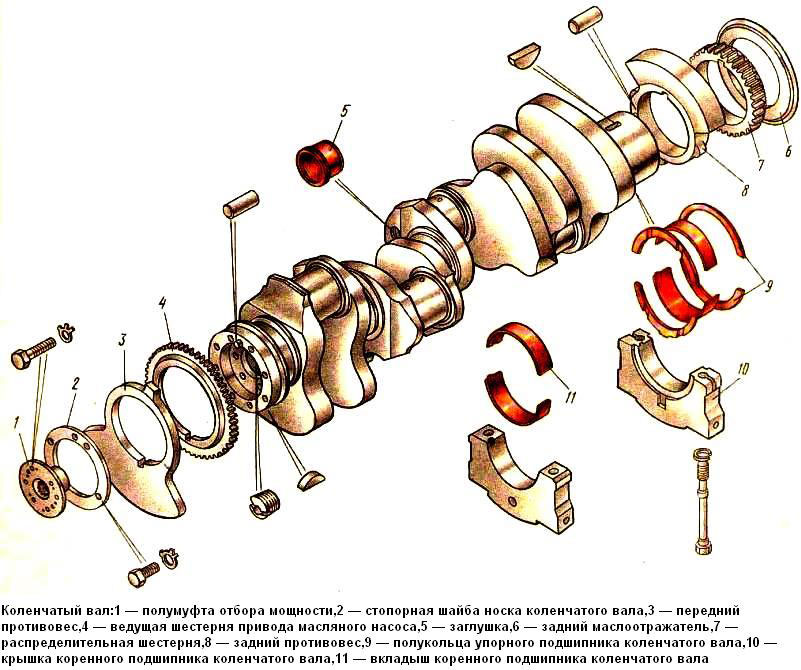

In internal combustion engines, the problem of friction is acute, especially relevant for the crankshaft - in a conventional four-cylinder engine, the shaft has at least five reference points (main journals) with a fairly large contact area. Even greater frictional forces can occur when the shaft jaws come into contact with the supports. To avoid this situation, the main journals of the crankshaft are made wider than their supports. However, such a solution causes axial play of the crankshaft, which is completely unacceptable - axial movements of the shaft lead to intensive wear of the parts of the crank mechanism and can cause their breakdowns.

To eliminate the backlash of the crankshaft, a thrust bearing is installed on one of its supports. This bearing differs from a conventional liner by the presence of lateral thrust surfaces in the form of a collar, removable rings or half rings. On the cheeks of the crankshaft at the installation site of this bearing, thrust annular surfaces are made - they are in contact with the half rings. Today, all piston engines are equipped with thrust bearings, while all parts have a fundamentally identical structure and principle of operation.

Types and design of crankshaft support half-rings

Two types of parts are used to reduce crankshaft play:

• Thrust half-rings;

• Washers.

Washers are one-piece rings that are mounted in the support of the rear main journal of the crankshaft. Half-rings are halves of rings that are mounted on the support of the rear or one of the middle main journals of the crankshaft. Today, half rings are most used, as they provide the best fit to the thrust surfaces of the crankshaft and wear out more evenly, and are convenient for installation / dismantling. In addition, washers can only be mounted on the rear main journal of the shaft, and the half rings can be mounted on any neck.

Structurally, the half-rings and washers are very simple. They are based on a solid bronze or stamped steel half-ring / ring, on which an anti-friction coating is applied, which reduces friction on the thrust surface on the shaft jaw. On the antifriction layer, two or more vertical (in some cases radial) grooves are made for the free passage of oil. Also, holes and fixing pins of various shapes can be provided on the ring / half ring to prevent the part from turning.

According to the material of manufacture of half rings are:

• Solid bronze;

• Steel-aluminum - aluminum alloy is used as an antifriction layer;

• Metal-ceramic - bronze-graphite spraying is used as an antifriction layer.

Bronze half-rings

Steel-aluminum half-rings

Metal-ceramic half-rings

Today, steel-aluminum and ceramic-metal half-rings are most widely used, and often they are installed in one engine on different sides of the support journal.

Half rings have two types of size:

• Nominal;

• Repair.

Parts of nominal size are installed on new engines and on engines with little wear on the thrust surfaces of the crankshaft and support. Repair size parts have an increased thickness (usually in increments of +0.127 mm) and allow you to compensate for the wear of the thrust surfaces of the crankshaft and support.

The crankshaft thrust bearing can be located on its various journals:

- On one of the central journals (in four-cylinder engines - on the third);

- On the rear neck (from the flywheel side).

In this case, two or four half rings are used. In the case of two half-rings, they are mounted in the grooves of the lower bearing cover (yoke cover). In the case of four half-rings, they are mounted in the grooves of the lower cover and the upper support. There are also engines with only one half-ring or one washer.

How to select and replace crankshaft half rings?

Over time, thrust half-rings, like any plain bearings, wear out, as a result of which the axial play of the crankshaft increases. The working backlash (gap) of the crankshaft lies in the range of 0.06-0.26 mm, the maximum - as a rule, should not exceed 0.35-0.4 mm. This parameter is measured using a special indicator mounted on the end of the crankshaft. If the backlash exceeds the maximum allowable, the thrust half-rings must be replaced.

The main types of diaphragm (diaphragm) oil pressure sensors

The sensor is of contact type. The device has a contact group - a movable contact located on the membrane, and a fixed contact connected to the device body. The position of the contacts is selected in such a way that at normal oil pressure in the system the contacts are open, and at low pressure they are closed. The threshold pressure is set by a spring, it depends on the type and model of the engine, so contact type sensors are not always interchangeable.

Rheostat sensor. The device has a fixed wire rheostat and a slider connected to the membrane. When the membrane deviates from the average position, the slider rotates around the axis by means of a rocking chair and slides along the rheostat - this leads to a change in the resistance of the rheostat, which is monitored by a measuring device or electronic unit. Thus, the change in oil pressure is reflected in the change in the resistance of the sensor, which is used for measurements.

When choosing half-rings, it is necessary to take into account an important nuance: not only the half-rings, but also the thrust surfaces of the crankshaft are subject to wear. Therefore, in new engines, when the crankshaft clearance increases, it is usually necessary to change only worn-out half-rings - in this case, it is necessary to purchase parts of the nominal size. And in engines with high mileage, wear of the thrust surfaces of the crankshaft becomes noticeable - in this case, it is necessary to purchase thrust rings of repair size.

It is necessary to choose new half-rings of the same types and catalog numbers as the old ones. It is important that they fully comply with the installation dimensions, and have an appropriate anti-friction coating. Especially the latter circumstance is important for motors in which half rings with different anti-friction coatings are initially installed. For example, on many VAZ engines, the rear semi-ring is ceramic-metal, and the front is steel-aluminum, and they are not interchangeable.

Replacement of half rings should be carried out in accordance with the instructions for maintenance and repair of the car. On some engines, it is necessary to remove the pallet and dismantle the lower cover of the thrust bearing, on other motors it will be necessary to make a more serious disassembly. When installing new rings, it is necessary to observe their orientation - the antifriction coating (on which grooves are usually provided) should be installed towards the crankshaft cheeks.

With the right choice and installation of half-rings, thrust bearings will ensure normal play of the crankshaft and reliable operation of the entire engine.

Post time: Aug-21-2023