Most modern piston internal combustion engines are equipped with a starting system with an electric starter. The transmission of torque from the starter to the crankshaft is carried out through a ring gear mounted on the flywheel - read all about this part, its purpose, design, correct selection and repair in the article.

What is a flywheel crown?

The flywheel ring gear (flywheel gear rim) is a flywheel part of piston internal combustion engines, a large-diameter gear that provides torque transmission from the starter to the engine crank mechanism.

The crown is both part of the KShM and the engine start system, it is rigidly mounted on the flywheel and engages with the starter gear. When starting, the torque from the starter is transmitted through the gear, ring and flywheel to the crankshaft and the rest of the engine systems, and after turning off the starting system, the ring acts as an additional mass of the flywheel.

Despite the simple design, the flywheel crown plays an important role in the operation of the engine, therefore, if replacement and repair is necessary, you should take a responsible approach to the choice of this part. And in order to make the right choice, you need to understand the design, characteristics and features of the crowns.

Types, design and characteristics of flywheel crown

First of all, it should be noted that today two types of flywheels are used - with a removable and non-removable crown. The most common are flywheels with a removable ring gear - these parts are simpler and more reliable in operation, they have high maintainability and allow you to save on the production and repair of cars. We will not consider flywheels with non-removable crowns here.

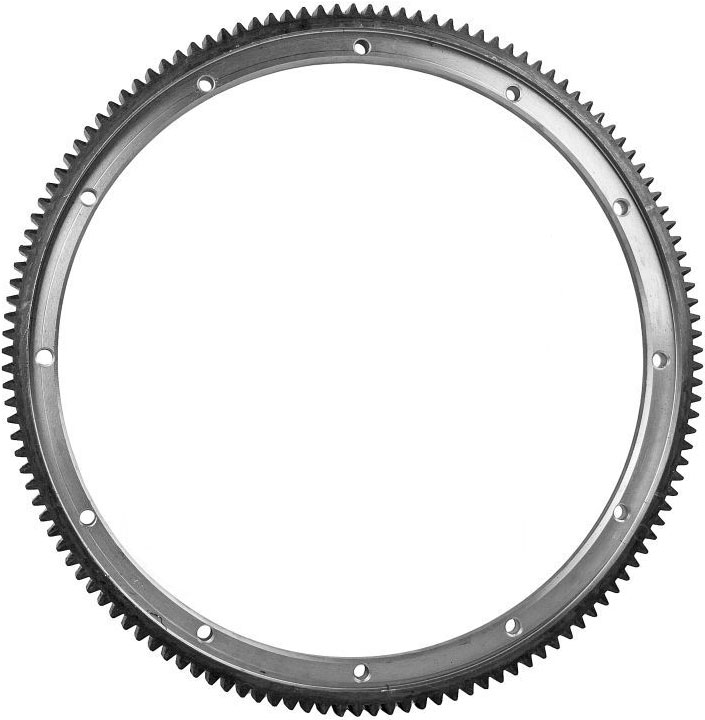

Structurally, all the crowns are very simple: it is a steel rim, on the outer surface of which teeth are turned to engage with the starter gear. The crown is made of various grades of steel, it is rigidly mounted on the flywheel and can be replaced if necessary.

Oil pressure sensors perform two main functions:

• Warning the driver about low oil pressure in the system;

• Alarm about low / no oil in the system;

• Control of absolute oil pressure in the engine.

The sensors are connected to the main oil line of the engine, which allows you to monitor the oil pressure and its presence in the oil system (this also allows you to check the operation of the oil pump, if it malfunctions, the oil simply does not enter the line). Today, sensors of various types and purposes are installed on engines, which needs to be described in more detail.

Pressurized flywheel ring

Bolt-on flywheel ring

In the second case, a flange with a number of bolt holes is provided on the inner surface of the crown, through which the part is mounted on the flywheel. Most often, such crowns are used on powerful engines, when starting which the toothed gear is subjected to significant loads. The bolted connection allows you to easily replace a worn crown without resorting to special tools or devices.

Flywheel crowns have three main characteristics:

• Diameter;

• Number of teeth Z;

• Meshing module (tooth module, wheel module) m.

The diameter and number of teeth of the crown lie within very wide limits, these characteristics may differ even for engines of the same model, but with different types of starters. Usually, the number of teeth lies in the range of 113 - 145 pieces, and the diameter of the crowns is from 250 mm on passenger car engines to 500 mm or more on powerful diesel engines.

The meshing modulus is the ratio of the diameter of the dividing circle to the number of teeth of the crown. The dividing circle is a conditional circle that divides the teeth of the gear into two parts (leg and head), it lies approximately in the middle of the height of the teeth. The value of the meshing modulus of the flywheel ring gears ranges from 2 to 4.25 in increments of 0.25. The meshing module is the most important characteristic in the selection of the crown and the starter gear - these parts must have the same m value, otherwise their teeth will not match, which will lead to intensive wear of parts, or the gear train will not work at all.

As a rule, the main characteristics of the rings (meshing module and number of teeth) are indicated by the manufacturer, these numbers can be applied directly to the crown. All characteristics must be taken into account when choosing crowns.

Issues of selection and replacement of the flywheel ring

During the operation of the engine, the teeth of the crown are subjected to intense wear, which can be aggravated by incorrect operation of the starter (for example, if Bendix does not immediately remove the gear from the crown when starting the engine or incorrectly positions the gear relative to the crown). Therefore, over time, the teeth of the crown grind and chip, which leads to a deterioration in starting the engine or even to the inability to perform it with the starter. If the teeth wear out, the crown must be turned over or replaced with a new one.

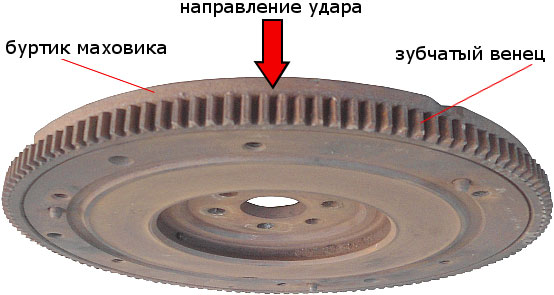

Dismantling of the pressed ring gear

The teeth of the crown wear out only from the outer upper corner, and the side of the teeth facing the flywheel remains intact. Therefore, when critical wear is reached, the crown can be removed, turned over, and installed with the whole side of the teeth outwards. When replacing, it is necessary to observe the correct installation of the rim so as not to knock down the balance of the flywheel. A special mark on the crown and flywheel helps to do this. With repeated wear, the crown simply changes to a new one.

To replace, you need to choose a toothed flywheel rim with the same characteristics that the old part had. Particular attention must be paid to the meshing module m - this characteristic should have the same meaning as the old crown. If, along with the flywheel crown, the starter gear also changes, then both parts must have the same engagement module. That is, when repairing, it is quite possible to use a gear and a ring with a different number of teeth, but at the same time their m should have the same value.

The crown is replaced on the dismantled flywheel in accordance with the repair instructions for this particular car. As a rule, pressed crowns can be removed and installed only after heating - the part expands when heated and can be removed or installed in its seat. After replacement, it may be necessary to balance the flywheel, this operation must be performed on a special stand. In the future, the crown does not need special maintenance.

With the right selection and replacement of the flywheel ring gear, the engine will start confidently, and the gear train will be subject to minimal wear.

Post time: Aug-18-2023