To supply compressed air to pneumatic tools, as well as in tractors for connecting pneumatic equipment of semi-trailers, special twisted pneumatic hoses are used. Read about what such a twisted hose is and how it works, about the hoses on the market and their operation, in this article.

Purpose of the twisted pneumatic hose

In services, service stations and tire shops, at various production sites, in transport and in many other areas, a variety of pneumatic tools are widely used. Pneumatic systems built on rigid pipelines and flexible hoses are used to drive pneumatic tools and to supply compressed air to the workplace. And in every workshop or on a semi-trailer you can find a pneumatic twisted (or spiral) hose.

A twisted pneumatic hose is a polymer hose rolled into a cylindrical spring. Moreover, the hose is made in such a way that in the free state it tends to curl up into a spring. This design gives the hose several useful qualities and properties:

- Compact storage of the hose when not in use;

- The hose takes up a minimum of space during operation, without interfering with the work;

- Automatic assembly of the hose into a compact spring after completion of work or after disconnecting the semi-trailer from the tractor.

The great advantage of a twisted hose over a conventional hose is the minimization of the space occupied during use. A conventional hose almost always has to be completely stretched, so it interferes with the work, is under your feet, can be accidentally damaged, etc. The twisted hose always tends to take the most compact shape, so when stretched, it does not interfere with the work, does not stretch on the floor, etc. All this ultimately increases labor efficiency and helps to save money. When used in a vehicle, the hose allows the semi-trailer to rotate relative to the tractor, preventing the possibility of damage. That is why today twisted pneumatic hoses are the most widespread.

Today, twisted pneumatic hoses have several main uses:

- Drive pneumatic tools in stationary conditions - in workshops, factories, etc.;

- Pneumatic tool drive on temporary sites, mainly on construction sites;

- Supply of compressed air from the tractor to the equipment of trailers or semi-trailers;

- Supply of compressed air for inflating wheels, purging and performing other operations.

In general, the twisted barrier is a modern solution that makes work more convenient and comfortable at no extra cost.

Types and design features of hoses

All twisted air hoses used today have essentially the same design. The basis of the hose is a polymer tube molded in the form of a twisted cylindrical spring. Usually, the hose is made of polyurethane or polyamide - these types of plastics have sufficient flexibility and reliability, as well as resistance to various negative conditions, aggressive environments, etc. (oils and fuels, high and low temperatures, humidity, sunlight, etc.). It is due to the molding of the tube in the form of a spring that the hose acquires its characteristics.

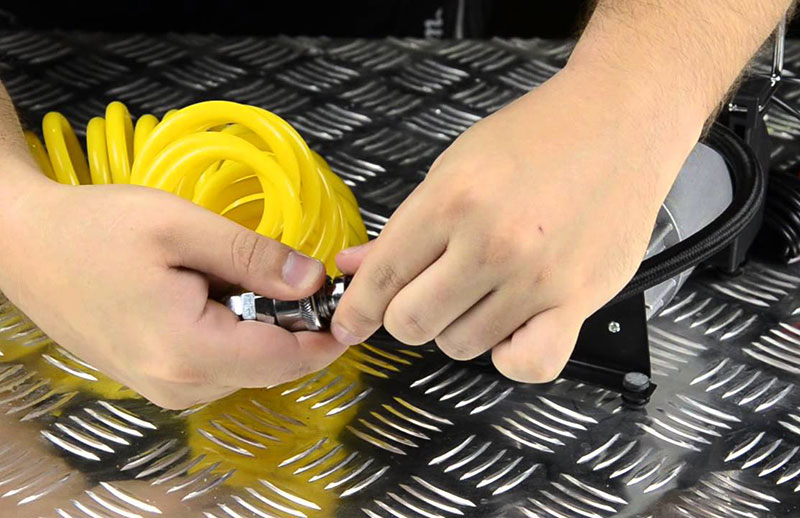

At both ends of the hose are attached fittings - connecting elements with which the hose is connected to a source of compressed air (to a compressor or to a pneumatic system) and a pneumatic tool. Since the hose is most often bent and can break at the attachment points of the fittings, protective springs or flexible plastic / rubber sleeves are provided here.

Hoses on the market differ in applicability, length, type of fittings and some performance characteristics.

According to the applicability, twisted pneumatic barriers are divided into two large groups:

- To power the pneumatic systems of semi-trailers and for use in vehicles in general;

- For power supply of pneumatic tools for various purposes (construction, installation, various spray guns, etc.).

Hoses can be equipped with three main types of fittings:

- Fittings with nuts, nuts of sizes M16, M18 and M22 are usually used;

- Threaded fittings under the nut;

- A variety of quick couplings (BRS);

- Conventional fittings for connection to another hose.

In automotive hoses, nut fittings or threaded fittings are most commonly used, with the same type of connectors installed at both ends of the hose (although the size of the thread or nuts may vary). On pneumatic hoses for tools, quick-release couplings are most often used, however, various combinations of fittings are possible - a BRS is attached on the side of the tool, on the reverse side there may be a fitting with a nut or a conventional fitting for connecting to another hose.

As for the length of the hose, there are options from 2.5 to 30 meters. In transport, twisted hoses with a length of 5.5 to 7.5 meters are most often used - these hoses are installed on domestic and foreign tractors / semi-trailers. Both short (in the workplace) and long hoses are used at production sites. In car services and various workshops, long hoses are widely used, which allow you to pull the tool at a considerable distance from the source of compressed air.

Among other things, twisted hoses have a maximum operating temperature, which is usually from 50 to 70 ° C. This parameter must be taken into account, since hoses often operate in harsh conditions (especially in cars), and compressed air in the pneumatic system can have a high temperature.

Finally, twisted pneumatic hoses have a specific set of colors, which allows you to accurately determine the purpose of each hose in the pneumatic system. In particular, red and yellow hoses are used on semi-trailers in various highways, and blue, green, gray and black hoses are widely represented on the market.

Issues of selection and operation of twisted pneumatic hoses

Today, the market offers a very wide range of pneumatic exhaust hoses, so it is important not to make a mistake when choosing and buying them. For the right choice, you need to consider four main parameters:

- Type of hose fittings. It is necessary to choose hoses with exactly those connections (type and size) that are used on the car, for connecting pneumatic tools, for connecting to the air line in the workshop, etc.;

- Hose length. It all depends on the conditions in which the hose will be operated: to connect a semi-trailer, hoses from 5.5 to 7.5 meters are needed, a short hose from 2.5 meters is enough to perform operations at the workplace, for large rooms with a remote location of the air line, a hose up to 30 meters long may be required;

- Hose material and maximum operating temperature. The choice should be made based on the temperature regime at which the hose will operate, as well as on the characteristics of the air coming from the pneumatic system or compressor;

- The color of the hose. This should be based both on the marking that has been adopted by the manufacturer of the vehicle or production equipment, and on the basis of the convenience of the workplace to be equipped.

The operation of twisted pneumatic hoses is simple and does not require special requirements. It is only recommended not to leave the hose in a stretched position for a long time, return the hose to the storage site every time after completion of work, try to prevent the hose from coming into contact with sharp or hot objects, and also prevent it from becoming entangled.

All this fully applies to the hoses of semi-trailers, but here it is necessary to additionally clean the hoses and connectors from dirt, and most importantly, regularly perform a visual inspection of the hoses and their fittings. If cracks, fractures or deformations of the fittings are found, the hose should be replaced, since the operation of the vehicle in this case becomes simply dangerous. If these simple recommendations are followed, twisted hoses will last a long time, providing a reliable supply of compressed air to consumers every day.

Post time: Aug-27-2023