In all carburetor and many injection engines, the accelerator drive is built according to a simple scheme with a mechanical transmission of force from the gas pedal by means of a cable. Read all about accelerator cables, their types, design and features, as well as the choice of a cable, its replacement and adjustment in the article.

What is an accelerator cable?

Accelerator cable (accelerator drive cable, throttle drive cable, accelerator thrust, throttle cable) - an accelerator control element for gasoline engines; twisted cable in the shell, through which the throttle valve (in the carburetor or throttle assembly) is driven from the gas pedal.

The change in the speed of the crankshaft (and, accordingly, the torque) of a gasoline internal combustion engine is carried out by changing the volume of the fuel-air mixture entering the cylinders. Changing the supply of the combustible mixture is carried out by a special regulating device - an accelerator. Carburetor flaps and related auxiliary devices, a throttle valve and an associated mass air flow sensor, and others can act as an accelerator in various types of engines. These devices are controlled by the driver using the gas pedal. In carburetor and many injection engines, the accelerator drive is built according to the classical scheme using mechanical traction - the accelerator cable.

The accelerator cable (accelerator rod) performs several functions:

● Mechanical connection of the carburetor or throttle flap to the gas pedal;

● Ensuring the opening of the damper in proportion to the degree of pressure on the gas pedal;

● Adjustment of the degree of opening of the damper depending on the angle of deflection of the gas pedal;

● Protection of the accelerator drive from negative environmental influences, water, pollution, etc.

Despite the widespread use of electronics, the accelerator cable does not lose its relevance and is used on many modern cars. Malfunction or breakage of the cable leads to a partial or complete loss of control over the operation of the engine, so this part should be replaced as soon as possible. But before you go to the store for a new cable, you need to understand their existing types, designs and features.

Types, design and characteristics of accelerator cables

All accelerator cables used today have the same design in principle. The basis of the part is a steel twisted cable (core) with a diameter of up to 3 mm, which is placed in a plastic protective sheath. At the ends of the cable, elements for attaching the cable to the accelerator and the gas pedal are rigidly fixed. The role of such elements can be bosses - steel cylindrical or barrel-shaped parts crimped around the ends of the cable, or hinges (hinges) - steel or metal parts with transverse holes for threaded fasteners, pin or ball. Also at the ends of the cable there are stoppers - plastic or metal cones that can move freely along the cable, resting on the boss (or lever / sector of the damper drive) and in the shell.

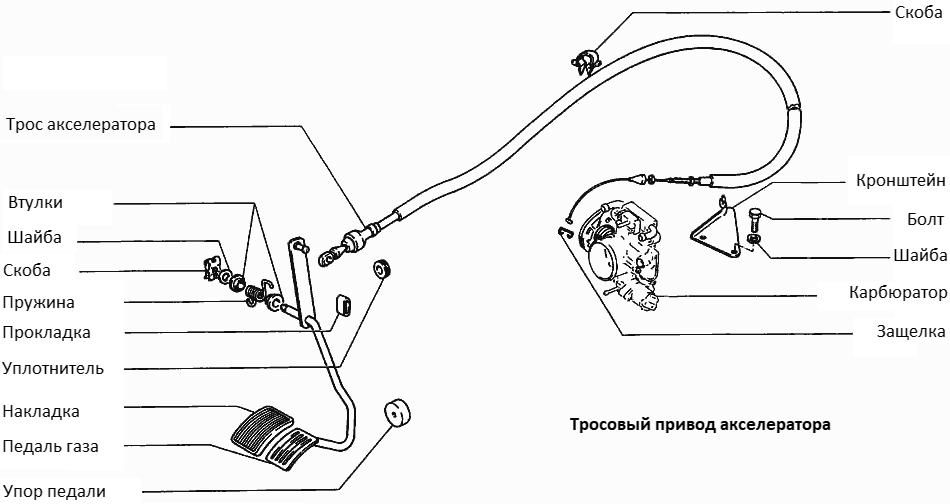

Accelerator cable drive

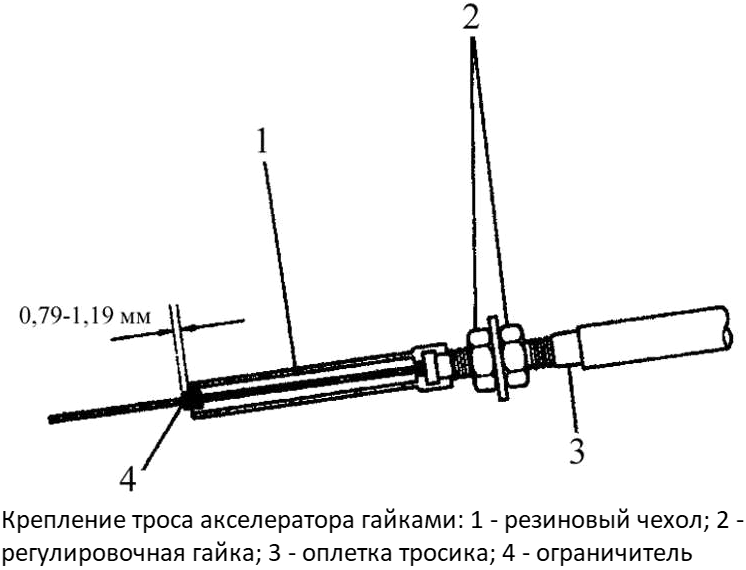

At the end of the protective sheath on the side of attaching the cable to the gas pedal there is an emphasis for mounting the cable to the body, this part is made in the form of a plastic or rubber sleeve, or a more complex unit with a threaded sleeve and nuts. On the side of attachment to the accelerator at the end of the shell there is an adjustment tip, which can have a design of two types:

● Threaded sleeve with nuts;

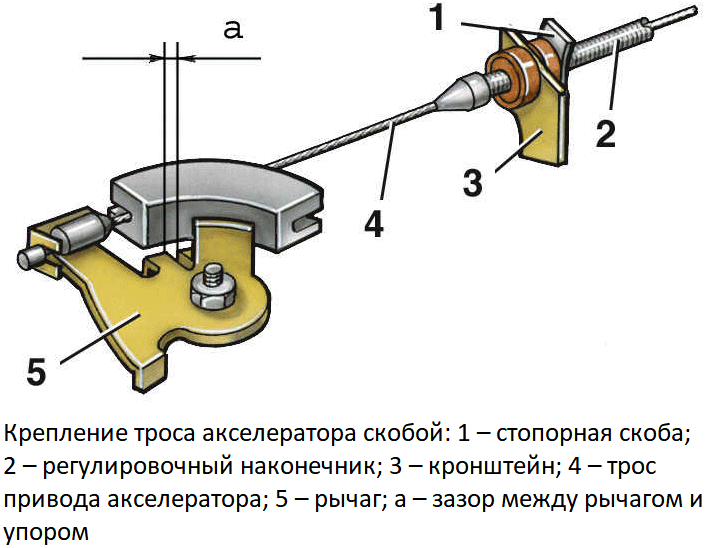

● Corrugated sleeve with thrust bracket(s).

In the first case, the tip is made in the form of a sleeve with an external thread, on which two nuts are screwed. The tip is installed in the hole in the bracket, where it is clamped with nuts - this provides both the fastening of the cable and the ability to adjust the entire accelerator drive.

In the second case, the tip is made in the form of a corrugated sleeve, on which one or two staples (wire or plate) can be rigidly fixed. The sleeve is placed in the hole of the bracket and fixed on one or both sides with brackets - in this case, the brackets play the role of nuts, but they can be relatively easily rearranged along the sleeve to adjust the accelerator drive.

Other elements can be provided on the cable: rubber corrugations to protect the ends of the cable from contamination and water ingress, protective bushings for passing the cable into holes in body parts, various kinds of clamps, etc. When assembling the cable, a special grease is added inside the shell, which ensures smooth movement (prevents jamming) of the core and its protection from corrosion due to exposure to water and gases.

The cable is installed between the gas pedal and the accelerator (carburetor, throttle assembly), the ends of the cable are attached directly to the pedal and the accelerator drive element (to the sector, lever) with the help of bosses or loops (hinges); The shell on the accelerator side is fixed in the bracket with nuts or brackets, and on the pedal side - in the body hole with the help of a stop (support sleeve). With this mounting, it is possible to move the cable inside the shell and transfer force from the pedal to the accelerator.

The cable drive is adjusted so that when the gas pedal is pressed all the way, the damper is fully open. This is ensured by changing the position of the adjusting tip of the cable relative to the bracket, which entails a change in the stroke of the cable. With the correct adjustment, the lever / sector of the damper, when fully opened, rests against the limiter and the end of the adjusting tip or does not reach it. In case of incorrect adjustment (the tip is too extended towards the accelerator), the lever / sector rests through the limiter against the end of the adjusting tip when the damper is not fully opened - in this situation, the engine does not gain full power when the pedal is fully depressed. With this adjustment, the length of the cable (core) always remains constant, and only its course changes, in this case there is no need to disassemble and assemble the cable, which significantly increases the reliability and safety of the accelerator drive.

It should be noted that there are twin accelerator cables, which are widely used on motorcycles and many cars. Structurally, this is an association of three cables that have a common connection point, one of the cables is connected to the pedal / throttle handle, and two to accelerators (for example, to the carburetor dampers of some motorcycle two-cylinder engines) or other parts. Usually, the branching point of the cables is enclosed in a plastic case or case that can be removed for maintenance or repair.

In technology, you can find other types of accelerator cables, but their design and principle of operation are similar to those described above, and the differences are only in some details and features of functioning.

Dual accelerator cable

How to choose, replace and maintain the accelerator cable

During the operation of the car, the accelerator cable is subjected to significant mechanical loads, heating and cooling, aggressive liquids and gases, etc. - all this leads to wear, corrosion, jamming or breakage of the part. A faulty cable should be removed and checked, and if it is impossible to fix the breakdown, completely replaced. Today, cables are not in short supply, so it makes sense to repair them only when wedging (the problem is solved by adding lubricant to the protective shell), and in case of mechanical damage, it is better to change them - this is both easier and safer.

For replacement, you should take the type of cable that was installed on the car earlier, and for vehicles under warranty, you must use parts of certain catalog numbers. If it is not possible to buy an original accelerator cable, then you can find an analogue - the main thing is that it fits in length (both the cable itself and its shell must have a certain length) and in the type of tips.

Replacement of the cable must be carried out in accordance with the instructions for repairing the car. In general, this work is quite simple: you need to disconnect the bosses or hinges from the accelerator and pedal, loosen the nuts or remove the brackets from the adjusting tip, and disconnect the stop from the pedal side. In this case, it may be necessary to dismantle the air filter, remove pipes and other interfering parts. The new cable is installed in reverse order, while the accelerator drive is adjusted. To adjust, you must fully press the gas pedal (the easiest way to do this operation is with an assistant), and by changing the position of the adjusting tip (screwing in or unscrewing the nuts, or changing the position of the brackets) to ensure that the damper is fully open. Such an adjustment can be periodically performed during the subsequent operation of the car.

With the correct selection, replacement and adjustment of the cable, the accelerator drive will work reliably in any conditions, ensuring effective control of the power unit.

Post time: Jul-14-2023