Each car has a cabin heating system associated with an engine cooling system. Electric heater taps are widely used to control the stove today - read about these devices, their types, design, principle of operation, as well as their selection and replacement in this article.

What is an electric heater faucet?

Electric heater valve (electric heater control valve, heater valve) - a component of the heating system of the passenger compartment / cabin of vehicles; A valve or valve to control the supply of coolant from the engine cooling system to the radiator (heat exchanger) of the heater.

An electrically controlled crane is analogous to a mechanical crane, but it is driven by a built-in electric motor or solenoid. This solution made it possible to abandon the cable drive and implement control of the heater using a button. Electric cranes make it possible to implement various schemes for heating the cabin and the operation of the engine cooling system, while they are easy to use, reliable in operation and have a simple design.

Types, design and principle of operation of an electric heater valve

Today's electrically controlled valves are divided into groups according to the type of shut-off element and its drive, and by the number of circuits (and, accordingly, pipes).

According to the number of circuits and pipes, heater valves are:

• Single-circuit/2-nozzle - conventional valves/valves;

• Double-circuit / 3-nozzle - three-way valves.

Double-branch valves are valves that can only open and close fluid flow. In such a valve, one pipe is an inlet pipe, the second is an exhaust pipe, and a locking element is located between them. The heater valve with two nozzles is used in conventional interior heating systems, it is located between the exhaust pipe of the engine cooling system and the inlet pipe of the stove radiator, providing control of the flow of hot coolant.

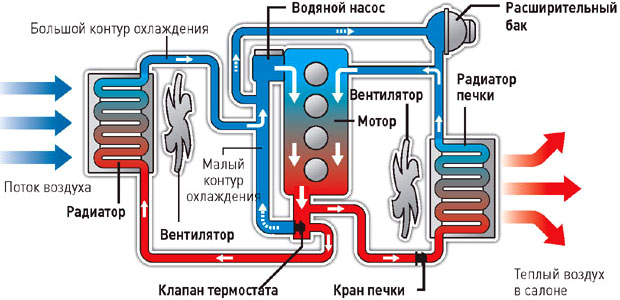

Typical scheme of engine cooling and interior heating systems

Three-way valves are three-way valves that can direct fluid flow into two different pipelines. This valve has one inlet pipe and two exhaust pipes, and the shut-off element is designed in such a way that it can direct fluid from the inlet pipe to one of the exhaust pipes, while blocking the second. The heater valve with three nozzles can be used in various interior heating systems: with a bypass, with an additional heater, etc.

According to the type of shut-off element and its drive, valves are:

• Slide gates driven by an electric motor;

• Solenoid-driven shut-offs.

The design of slide cranes is simple. They are based on a plastic molded body with pipes, inside of which there is a swivel plate in the form of a solid sector or sector with holes according to the size of the pipes. A compact electric motor with a simple gear reducer is installed on the body, with the help of which the plate is rotated. In valves with two nozzles (double-circuit), both pipes are located opposite each other, between them there is a plate. In valves with three nozzles, there is an inlet pipe on one side, and two exhaust pipes on the other.

A heater valve with an electric motor works as follows. When the stove is turned off, the tap plate is located between the pipes, blocking the flow of liquid - in this case, the hot liquid does not enter the heater radiator, the interior heating system does not work. If it is necessary to turn on the stove, the driver presses the button on the dashboard, current is supplied to the electric motor of the crane, it turns the plate and opens the path of the coolant - the heater radiator heats up, the interior heating system starts working. To turn off the stove, the driver presses the button again, all processes occur in reverse order, and the stove turns off.

A heater valve with three nozzles in the presence of a bypass in the heating system also works easily. When the stove is turned off, the swivel plate is in such a position that the coolant passes through the valve and enters the inlet of the engine cooling system (pump) through the exhaust pipeline. When the stove is turned on, the plate turns, closes one outlet and opens the second - now the flow of liquid freely passes into the heater radiator, and from it enters the exhaust pipeline and the inlet of the engine cooling system. When the stove is turned off, all processes occur in reverse order.

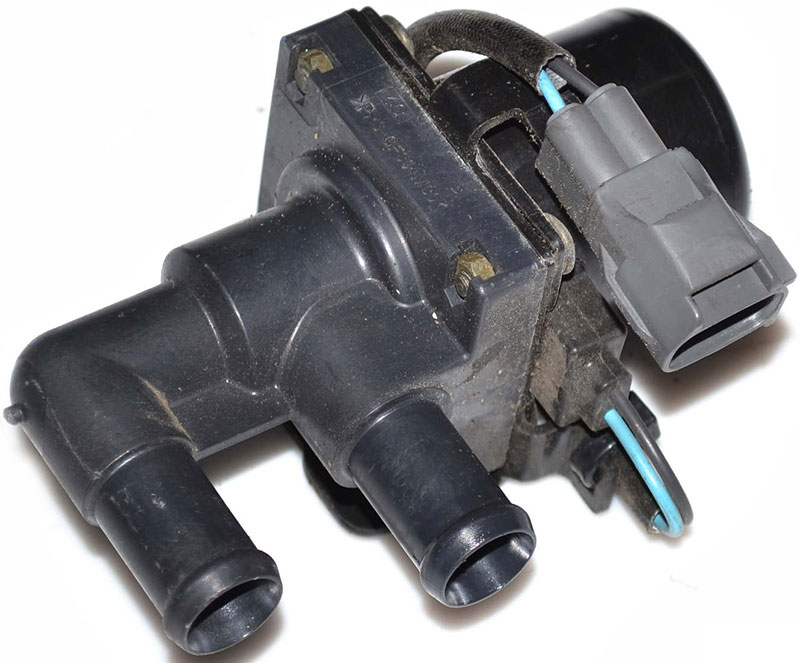

The design of shut-off solenoid valves is different. They are based on a plastic case, inside of which there is a lifting gate in the form of a truncated cone. In the closed position, the shutter sits on its saddle, ensuring that the flow of fluid is blocked. The gate is connected by means of a rod to the solenoid armature, which is installed on the crane body. Double-circuit valves can be single- and double-solenoid. In the first case, both locking elements are located on the solenoid rod, in the second, each locking element is controlled by its own solenoid.

Heater faucet with solenoid

The operation of the heater solenoid valve is also simple. The valves are normally open - without voltage on the solenoid, the shutter is raised by a spring, the channel is open. When the engine starts, voltage is applied to the solenoid and the valve closes. When the stove is turned on, the solenoid is de-energized, the tap opens and provides hot liquid to the heating radiator. When the stove is turned off, voltage is again applied to the solenoid and the tap closes. The double-circuit valve works similarly, but one of its circuits always closes when the ignition is turned on - this prevents the supply of coolant to the heater radiator, the liquid goes along the bypass. When the stove is turned on, the circuits are switched, the coolant enters the heater radiator, when the stove is turned off, the tap returns to its original position. Both solenoids of a double-circuit valve never open or close at the same time (except for a complete de-energization when both gates are open).

The nozzles of valves of all types are serrated, this shape ensures a tight fit of rubber pipelines. Installation of pipelines on pipes is carried out using metal clamps, the crane itself usually hangs freely on pipelines (since it has a low mass). The crane is connected to the electrical system using a standard electrical connector.

Today, electric heater valves are widely used on domestic and foreign cars, they have practically replaced mechanical analogues and made the control of the interior stove more convenient.

Issues of selection and replacement of the heater valve

The heater valve is very important for the operation of the interior / cabin heating system, but the selection and replacement of this part in most cases does not cause any problems. To choose the right crane, you must follow a few recommendations:

• The supply voltage of the crane motor must correspond to the voltage of the vehicle's on-board electrical network - 12 or 24 V;

• The type of crane - 2 or 3 pipes - must correspond to the scheme of the interior heating system. For conventional systems, a crane with two nozzles is needed, for systems with a bypass, a valve with three nozzles is needed. Also, a faucet with three nozzles can be used to create a heating system with an additional heater;

• The diameter of the pipes should correspond to the diameter of the pipelines of the heating system, but if necessary, adapters can be used;

• There should be one type of electrical connector on the crane and the car. If necessary, it is necessary to replace the type of connector on the car;

• The crane must have suitable dimensions for its installation.

Replacement of the heater valve must be carried out after draining the coolant, metal clamps must be used for installation. It is necessary to monitor the correct installation of the valve - place its inlet and outlet pipes in accordance with the direction of the liquid. For convenience, arrows are applied to the nozzles indicating the direction of fluid flow. If the usual 2-nozzle valve is installed incorrectly, the system will work, but improper installation of the 3-nozzle valve will make the system completely inoperable. With the correct and reliable installation of the crane, the stove will start working immediately, providing warmth and comfort in the car.

Post time: Aug-05-2023