The basis of the pneumatic system of MAZ trucks is a unit for air injection - a reciprocating compressor. Read about MAZ air compressors, their types, features, design and principle of operation, as well as proper maintenance, selection and purchase of this unit in this article.

What is a MAZ compressor?

The MAZ compressor is a component of the brake system of trucks of the Minsk Automobile Plant with pneumatic drive mechanisms; a machine for compressing the air coming from the atmosphere and supplying it to the units of the pneumatic system.

The compressor is one of the main components of the pneumatic system, it has three main functions:

• Air intake from the atmosphere;

• Compression of air to the required pressure (0.6-1.2 MPa, depending on the mode of operation);

• Supply of the required volume of air to the system.

The compressor is installed at the inlet to the system, providing compressed air in a volume sufficient for the normal functioning of all components of the brake system and other consumers. Incorrect operation or failure of this unit reduces the effectiveness of the brakes and impairs the handling of the vehicle. Therefore, a faulty compressor must be repaired or replaced as soon as possible, and in order to make the right choice of unit, you need to understand its types, features and characteristics.

Types, characteristics and applicability of MAZ compressors

MAZ vehicles use single-stage piston air compressors with one and two cylinders. The applicability of the units depends on the model of the engine installed on the car, the two basic models are most widely used:

- 130-3509 for vehicles with YaMZ-236 and YaMZ-238 power plants of various modifications, MMZ D260 and others, as well as with new power plants YaMZ "Euro-3" and higher (YaMZ-6562.10 and others);

- 18.3509015-10 and modifications for vehicles with TMZ 8481.10 power plants of various modifications.

The basic model 130-3409 is a 2-cylinder compressor, on the basis of which a whole line of units has been created, their main parameters are presented in the table:

| Compressor model | Productivity, l/min | Power consumption, kW | Actuator type |

|---|---|---|---|

| 16-3509012 | 210 | 2,17 | V-belt drive, pulley 172 mm |

| 161-3509012 | 210 | 2,0 | |

| 161-3509012-20 | 275 | 2,45 | |

| 540-3509015,540-3509015 B1 |

210 | 2,17 | |

| 5336-3509012 | 210 |

These units provide these characteristics at a nominal shaft speed of 2000 rpm and maintain up to a maximum frequency of 2500 rpm. Compressors 5336-3509012, designed for more modern engines, operate at shaft speeds of 2800 and 3200 rpm, respectively.

Compressors are mounted on the engine, connecting to its cooling and lubrication systems. The head of the unit is water-cooled, the cylinders are air-cooled due to the developed fins. Lubrication of rubbing parts is combined (various parts are lubricated under pressure and oil spray). The differences between the modifications of the compressors of the base model 130-3409 are the different position of the inlet and outlet pipes of the cooling and lubrication system, and the design of the valves.

Unit 18.3509015-10 - single-cylinder, with a capacity of 373 l / min at a rated shaft speed of 2000 rpm (maximum - 2700 rpm, maximum at reduced outlet pressure - 3000 rpm). The compressor is mounted on the engine, is driven by the gears of the gas distribution mechanism, is connected to the cooling and lubrication systems of the motor. Head cooling is liquid, cylinder cooling is air, lubricant is combined.

A separate group consists of compressors 5340.3509010-20 / LK3881 (single-cylinder) and 536.3509010 / LP4870 (two-cylinder) - these units have a capacity of 270 l / min (both options) and a drive from timing gears.

Compressors of all models are supplied in various configurations - with and without pulleys, with unloading (with a mechanical pressure regulator, "soldier") and without it, etc.

Design and principle of operation of MAZ compressors

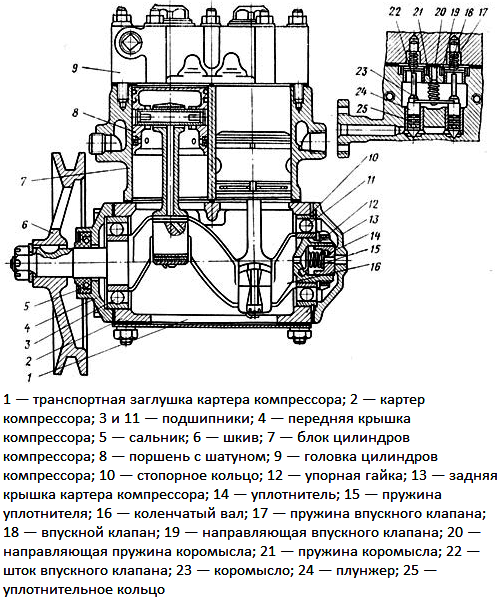

MAZ compressors of all models have a fairly simple device. The basis of the unit is the cylinder block, in the upper part of which the cylinders are located, and in the lower part there is a crankshaft with its bearings. The crankcase of the unit is closed with front and rear covers, the head is mounted on the block through the gasket (gaskets). In the cylinders there are pistons on the connecting rods, the installation of these parts is carried out through the liners. A pulley or drive gear is installed on the toe of the crankshaft, the pulley / gear is keyed mounting, with fixation against longitudinal displacements with a nut.

The block and crankshaft have oil channels that supply oil to the rubbing parts. Pressurized oil flows through channels in the crankshaft to the connecting rod journals, where it lubricates the interface surfaces of the liners and the connecting rod. Also, little pressure from the connecting rod journals through the connecting rod enters the piston pin. Further, the oil drains and is broken by rotating parts into small droplets - the resulting oil mist lubricates the cylinder walls and other parts.

In the head of the block there are valves - intake, through which air from the atmosphere enters the cylinder, and discharge, through which compressed air is supplied to subsequent units of the system. The valves are wafer-shaped, held in the closed position with the help of coiled springs. Between the valves there is an unloading device, which, when the pressure at the compressor outlet rises excessively, opens both valves, allowing free air passage between them through the discharge channel.

The design of the two-cylinder compressor MAZ

The working principle of air compressors is simple. When the engine starts, the shaft of the unit begins to rotate, providing reciprocating movements of the pistons through the connecting rods. When the piston is lowered under the influence of atmospheric pressure, the intake valve opens, and the air from, after passing through the filter to remove contaminants, fills the cylinder. When the piston is raised, the intake valve closes, at the same time the discharge valve is closed - the pressure inside the cylinder increases. When a certain pressure is reached, the discharge valve opens and air flows through it into the pneumatic system. If the pressure in the system is too high, then the discharge device comes into operation, both valves open, and the compressor idles.

In two-cylinder units, the cylinders operate in antiphase: when one piston moves down and air is sucked into the cylinder, the second piston moves upwards and pushes compressed air into the system.

Issues of maintenance, repair, selection and replacement of MAZ compressors

An air compressor is a simple and reliable unit that can work for years. However, to achieve this result, it is necessary to regularly perform the prescribed maintenance. In particular, the tension of the drive belt of two-cylinder compressors should be checked daily (the deflection of the belt should not exceed 5-8 mm when a force of 3 kg is applied to it), and, if necessary, adjustment should be made using a tensioner bolt.

Every 10-12 thousand km of run, you need to check the seal of the oil supply channel in the rear cover of the unit. Every 40-50 thousand km of run, the head should be dismantled, it should be cleaned, pistons, valves, channels, supply and outlet hoses, and other parts. The reliability and integrity of the valves are immediately checked, if necessary, they are replaced (with lapping). Also, the unloading device is subject to inspection. All work must be carried out in accordance with the instructions for the maintenance and repair of the car.

If individual parts of the compressor break, they can be replaced, in some cases it is necessary to completely change the compressor (deformations and cracks on the head and block, general wear of the cylinders and other malfunctions). When choosing a new compressor, it is necessary to take into account the model and modification of the old unit, as well as the model of the power unit. In general, all units based on 130-3509 are interchangeable and can operate on any YaMZ-236, 238 engines and their numerous modifications. However, it should be borne in mind that some of them have a capacity of 210 l / min, and some have a capacity of 270 l / min, and the new compressors of the model 5336-3509012 of various modifications usually operate at high speeds. If the engine used to have a compressor with a capacity of 270 l / min, then the new unit must be the same, otherwise the system simply will not have enough air for normal operation.

Single-cylinder compressors 18.3509015-10 are presented in a small number of modifications, and not all of them are interchangeable. For example, the compressor 18.3509015 is designed for KAMAZ 740 engines and is not suitable for YaMZ engines. In order to avoid mistakes, it is necessary to specify the full names of compressors before buying them.

Separately, it is worth mentioning the German compressors KNORR-BREMSE, which are analogues of the above models of units. For example, two-cylinder compressors can be replaced by unit 650.3509009, and single-cylinder compressors by LP-3999. These compressors have the same characteristics and installation dimensions, so they easily take the place of domestic ones.

With the right choice and installation, the MAZ compressor will work reliably, ensuring the functioning of the vehicle's pneumatic system in any operating conditions.

Post time: Aug-05-2023