Installation of springs on the frame of the vehicle is carried out with the help of supports built on special parts - fingers. You can learn all about spring pins, their existing types, design and features of work in the suspension, as well as the correct choice of fingers and their replacement, in this article.

What is a spring pin?

Spring pin is a common name for parts in the form of rods with different mounting methods (threaded, wedge, cotter pin), protruding as axles or fasteners in spring suspensions of vehicles.

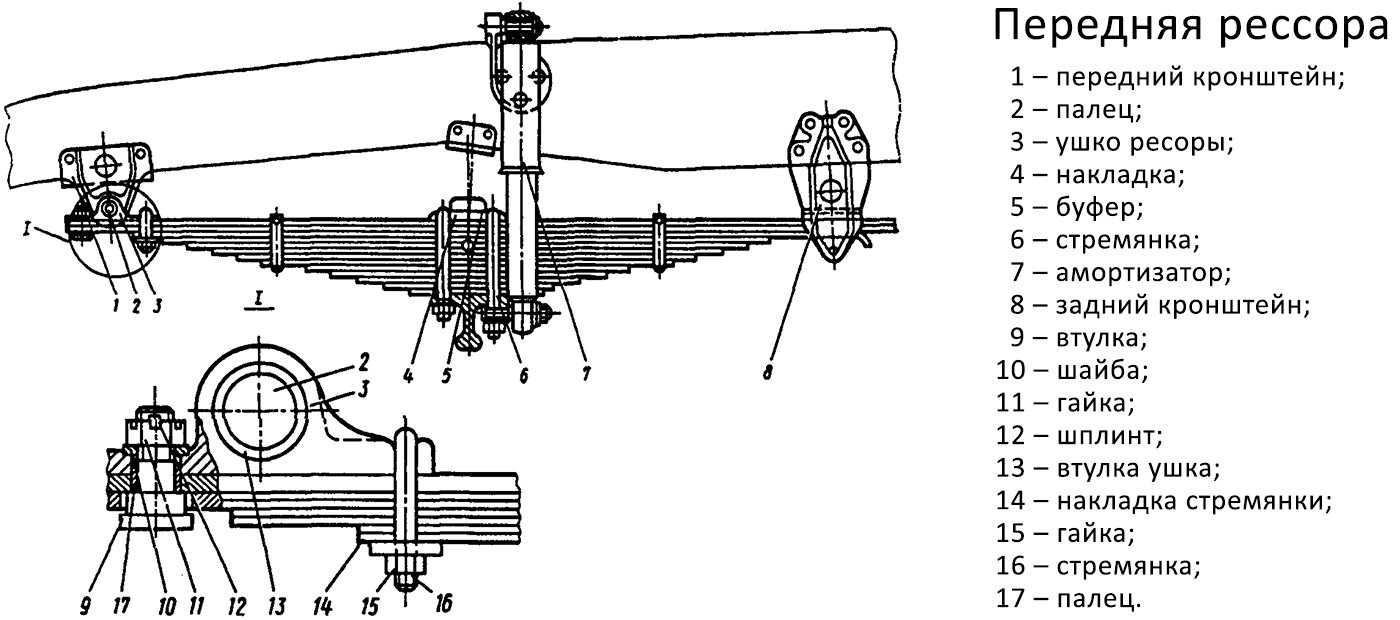

Spring suspension, invented in the XVIII century, is still relevant and is widely used in road transport. Springs act as elastic elements, which, due to their springy properties, smooth out shocks and shocks when driving a car over road bumps. The most widely used are semi-elliptical springs with two points of support on the frame - articulated and sliding. The hinge point provides the ability to rotate the spring relative to the frame, and the sliding point provides changes in the length of the spring during deformations that occur at the moments of overcoming the unevenness of the road surface. The axis of the hinged support, which is located in front of the spring, is a special element - the finger of the spring eye (or the finger of the front end of the spring). Rear sliding spring supports are most often made on bolts and other parts, but sometimes they also use fingers of various designs.

Leaf spring suspension and the place of the fingers in it

Spring pins are important parts of the suspension, constantly working under high loads (even when the car is not moving), so they are subject to intense wear and periodically need to be replaced. But before buying new fingers, you should understand the design and features of these parts.

Types, design and features of spring pins

The pins of the springs are classified according to the functions performed in the suspension (and, accordingly, according to the place of installation), and according to the method of installation.

According to the purpose (functions), the fingers are divided into three main groups:

● The fingers of the ear (front end) of the spring;

● Pins of the rear spring support;

● Various mounting pins.

Almost all spring suspensions have an ear finger, which is the main element of the front hinged fulcrum of the front and rear springs. This finger performs several functions:

- Acts as the axis (kingpin) of the hinged fulcrum;

- Provides a mechanical connection of the spring lug with the bracket located on the frame;

- Provides the transfer of forces and torques from the wheel to the vehicle frame.

Installing the spring pin on the nut

The pins of the rear support can not be found in all spring suspensions, often this part is replaced with bolts or brackets without any threaded fasteners. These fingers can be divided into two main types:

● Single fingers fixed in the rear brackets of the spring (more precisely, in the liners of the bracket);

● Double fingers gathered in an earring.

The most commonly used single fingers are located in the rear bracket, the spring rests on this finger (directly or through a special rigid gasket). Double fingers are used much less frequently, and usually on cars of small weight (for example, on some UAZ models). The fingers are assembled in pairs with the help of two plates (cheeks), forming an earring for hanging the spring: the upper finger of the earring is installed in the bracket on the frame, the lower finger is installed in the eyelet on the back of the spring. This fastening allows the rear end of the spring to move horizontally and vertically when the wheel moves over uneven roads.

Various kinds of mounting pins are used to connect the spring plate package to the eyelet (or spring plate, at the end of which a loop is formed). Both pins and bolts can be used for connection in combination with various plastic and rubber bushings.

According to the method of installation, the fingers of the springs are divided into three types:

1.With fixation with transverse bolts of small diameter (jamming);

2.With nut fixation;

3.With cotter pin fixation.

In the first case, a cylindrical finger is used, on the lateral surface of which two transverse semicircular grooves are made. The bracket has two transverse bolts that fit into the grooves of the pin, ensuring its jamming. With this installation, the finger is securely held in the bracket, it does not rotate around the axis and is protected from falling out under the influence of shock loads and vibrations. Fingers of this type are widely used in trucks, including domestic KAMAZ trucks.

In the second case, a thread is cut at the end of the finger, on which one or two nuts with thrust washers are screwed. Both conventional nuts and crown nuts can be used, complete with a cotter pin, which is installed in the transverse hole in the pin, and reliably counters the nut.

In the third case, fingers are used, fixed only with a cotter pin, which acts as a stop to prevent the part from falling out of the bracket. Additionally, a thrust washer is used with the cotter pin.

The fingers of the first and second types are used in the front supports of the springs, the fingers of the third type are used in the rear supports of the springs.

In a separate group, you can take out the fingers used in spring earrings. In one cheek, the fingers are pressed, for which an extension with a longitudinal notch is performed under their heads - the finger with this extension is installed in the hole in the cheek, and rigidly fixed in it. As a result, a detachable connection is created, thanks to which the earring can be easily mounted and dismantled, and, if necessary, disassembled to replace one finger.

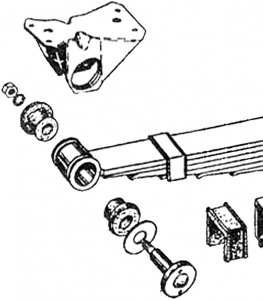

The pins of the front supports are mounted in the brackets through a solid or composite sleeve. In trucks, solid steel bushings are most often used, in which the pins are installed through two ring rubber seals (cuffs). In lighter cars, composite bushings are widely used, consisting of two rubber bushings with collars connected by outer and inner steel bushings - this design is a rubber-metal hinge (silent block), which reduces the overall level of vibration and suspension noise.

For the normal operation of the pin of the front support (spring eyelet), it must be lubricated - for this purpose, an L-shaped channel is performed in the fingers (drilling at the end and in the side), and a standard grease fitting is mounted at the end on the thread. Through the oiler, grease is injected into the finger channel, which enters the sleeve and, due to pressure and heating, is distributed throughout the gap between the sleeve and the pin. To evenly distribute the lubricant (as well as to properly install the part in the bracket), longitudinal and transverse grooves of various shapes can be performed in the pin.

Spring lug pin with two bolts

Spring lug pin with nut

fixation Pin of the rear spring support on the cotter pin

How to pick up and replace the spring pin

During the operation of the vehicle, all fingers of the springs are subjected to significant mechanical loads, as well as the effects of negative environmental factors, which leads to their intensive wear, deformation and corrosion. It is necessary to check the condition of the fingers and their bushings at each TO-1, during the inspection it is necessary to visually and instrumentally assess the wear of the fingers and bushings, and, if it is more than permissible, change these parts.

Only those fingers and mating parts recommended by the vehicle manufacturer should be taken for replacement. The use of other types of parts can lead to premature wear and suspension breakdowns, and self-production of fingers can also have a negative result (especially if the steel grade is incorrectly selected). It is necessary to change the spring pin in accordance with the instructions for repair and maintenance of the vehicle. Usually, this operation is carried out as follows:

1.Hang out a part of the car from the side of the spring to be repaired, unload the spring;

2.Disconnect the shock absorber from the spring;

3.Release the pin - unscrew the nut, unscrew the bolts, remove the cotter pin or perform other operations in accordance with the type of pin attachment;

4.Remove the finger - knock it out or pull it out of the sleeve using a special device;

5.Inspect the sleeve and, if necessary, remove it;

6.Install new parts, after lubricating;

7.Reverse assemble.

It should be noted that in some cases it is possible to remove the finger only with the help of special pullers - this device must be taken care of in advance. The puller can be purchased or made independently, although factory products work much more efficiently.

After replacing the finger, it is necessary to fill the grease into it through a grease fitting and then perform this operation with appropriate maintenance.

If the spring pin is selected and replaced correctly, the car's suspension will serve reliably in all conditions, providing comfortable and safe movement.

Post time: Jul-11-2023