In modern vehicles, an auxiliary system is provided that provides comfortable movement during precipitation - a wiper. This system is driven by a geared motor. Read all about this unit, its design features, selection, repair and replacement in the article.

Purpose and functions of the wiper gear motor

A wiper geared motor is a low-power electric motor combined with a gearbox that acts as a drive for vehicle wipers.

Vehicles must be operated in all weather conditions, including during precipitation of all types - rain and snow. Also, the operation of a car, tractor, bus or any other equipment should not be affected by the ingress of water and dirt on the windshield. All this is provided by an auxiliary system mounted at the front and / or rear window - windshield wipers. Directly cleaning the glass is performed by special movable brushes, the drive of which is provided by a built-in electromechanical unit - a geared motor.

The wiper gear motor has three main functions:

● Wiper blade drive;

● Ensuring reciprocating movement of the wiper blades;

● Stop the brushes in one of the extreme positions when the wiper is turned off.

The condition and functioning of the geared motor depends not only on the operation of the wiper, but on the confident and safe operation of the vehicle. Therefore, the faulty unit must be repaired or replaced. But before you go to the store for a new geared motor, you should understand the design, operation and features of these automotive components.

Design, operation and features of wiper geared motors

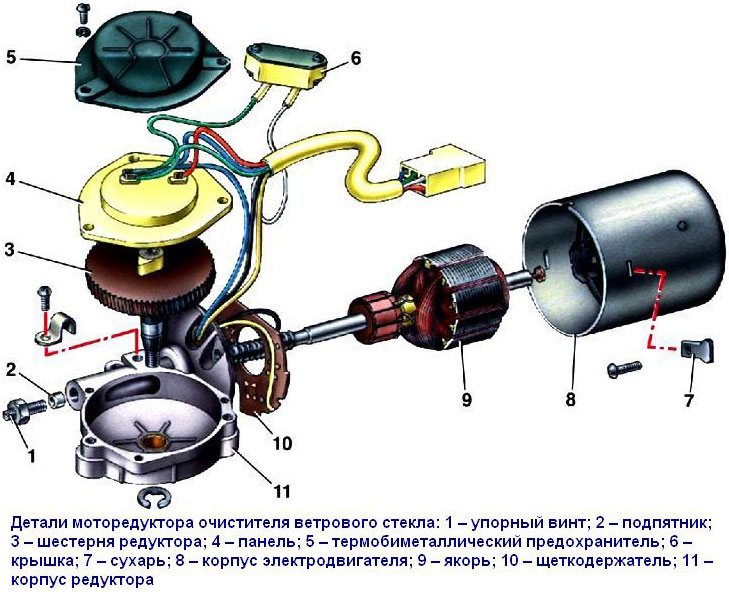

On most modern vehicles, worm-type electric geared motors are used. The design of such a unit is generally quite simple, it consists of two main parts:

● Low-power drive motor;

● A gearbox placed in a housing rigidly mounted on the motor housing on the side of its shaft.

The electric motor is most often commutator, direct current, for a supply voltage of 12 or 24 V. To protect the internal parts of the engine from negative environmental influences (water, dust, various contaminants), a sealed case or an additional protective cover is used. This design allows you to place the wiper gear motor in places of the car body that have minimal protection.

The gearbox is of the worm type, which provides a change in the speed of the output shaft simultaneously with a 90-degree rotation of the torque flow. Structurally, gearboxes are of two types:

● With direct drive of the driven gear from the worm;

● With driven gear drive through intermediate (intermediate) gears of small diameter.

The general structure of the wiper gear motor

In the first case, the gearbox consists of only two parts: a worm connected to the motor shaft and a driven gear with concave teeth. In the second case, the gearbox consists of three or four parts: a worm connected to an intermediate gear (or two gears) of small diameter, and a driven gear. The worm is most often metal, single-pass, often it is cut directly onto the shaft of the electric motor. The front part of the worm (or the shaft on which the worm is cut) is located in the sleeve (metal, ceramic) or bearing, and to compensate for the axial forces arising from the worm, the rear part of the engine shaft rests on the thrust bearing located in the rear end of the housing.

The driven gear of the gearbox is mounted on a steel shaft that extends beyond the gearbox housing, a crank is mounted on its protruding part, which, in turn, is connected to the wiper trapezoid (connecting rod rack and rods). The crank, together with the trapezoid, converts the rotational motion of the gear into the reciprocating motion of the wiper blades.

The gearbox is placed in a sealed housing mounted on the motor housing from the side of its shaft. The gearbox housing also accommodates elements of automatic wiper control:

- Limit switch - contacts for turning off the geared motor in one of the extreme positions of the brushes;

- Thermobimetallic fuse for turning off the engine when it heats up in case of jamming or overloads.

The limit switch of the electric motor ensures that the brushes stop in one of the extreme positions - in the lower or in the upper, depending on the type of wiper and the design features of the vehicle cab. These contacts are opened by a special cam on the gear, and a constant closure is provided by a spring. The operation of the limit switch is described below.

The thermobimetallic fuse is reusable, it is included in the break in one of the power wires of the electric motor connected to the contact of the limit switch. The fuse ensures that the power supply circuit of the electric motor is opened when it is closed or overloaded due to jamming of the armature.

Mounting racks (most often three pieces) are usually made on the gearbox housing, with the help of which the entire unit is mounted directly on the body part or on a metal bracket (which, in turn, can also act as the basis for mounting the wiper trapezoid). Mounting holes are made in the bracket, in which rubber or plastic bushings are installed, providing a tight installation of the unit, as well as damping shocks and vibrations. The geared motor of the front wiper is mounted under or above the windshield in suitable niches (for example, in the air intake of the heater), the rear wiper is mounted under the trim of the rear or rear door. To connect the node to the car's electrical network, a standard connector is provided on the wiring harness or on the body.

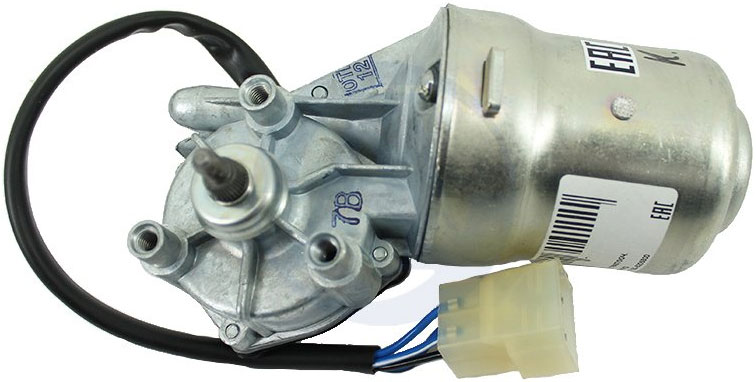

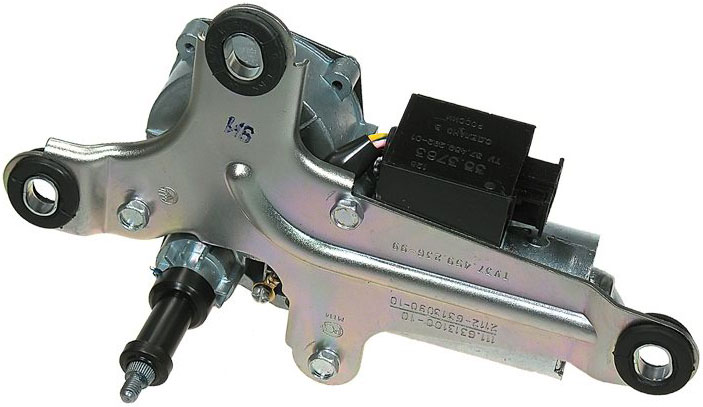

Windshield

wiper gear motor Shaft side wiper gear motor

The geared motor works as follows. When the wiper is turned on, the current enters the engine through the limit switch and the bimetallic fuse, its shaft begins to rotate, and the worm gearbox, together with the crank and trapezoid, provides reciprocating movement of the brushes. When the wiper is turned off, the engine power circuit does not open immediately, but only at the moment the cam reaches the gear of the limit switch contacts - in this case, the brushes stop in the extreme position and do not move further. The same happens when the wiper is transferred to intermittent operation, but after a certain pause (it is set by the wiper breaker relay), the current is supplied to the motor bypassing the limit switch, the brushes make several oscillations, and stop again in the extreme position, then the cycle repeats.

Most wiper geared motors have gearboxes with an average gear ratio of 50:1, which ensures the operation of the blades at a frequency of 5-60 cycles (swinging in both directions) per minute in various modes (constant and intermittent).

How to properly select, repair and replace a wiper gear motor

If the geared motor fails, the operation of the wiper is disrupted until the glass cannot be completely cleaned. Malfunctions can be manifested by various noises and squeaks from the gearbox. To identify the type of breakdown, it is necessary to check the assembly, and then repair or replace it in the assembly. Most often, problems arise in the gearbox - gear wear occurs and damage to bushings / bearings / thrust bearings, less often malfunctions are observed in the electric motor. You can try to restore the gearbox, but with uniform wear of the gears, it is easier to replace the assembly assembly.

Only the gearbox motor of the type that was installed on the car by the manufacturer should be taken for replacement. If this is not possible for any reason, then you can try to install a unit of a different type or model, but most often in this case there are difficulties in installation (since the mounting holes and dimensions of the parts do not match) and in subsequent adjustment. It is necessary to carry out work in accordance with the instructions for the repair of the vehicle.

With the correct selection and replacement of the geared motor, the wiper will start working without additional adjustments, providing comfortable driving in any weather.

Post time: Jul-11-2023