Many cars and tractors use an exhaust system, which includes auxiliary parts - intake pipes. Read all about intake pipes, their existing types, design and applicability, as well as the correct selection and replacement of these parts in this article.

What is a suction pipe?

The intake pipe (intake pipe pipe) is an element of the exhaust gas exhaust system of internal combustion engines; A short pipe of a certain profile and cross-section, which ensures the reception of gases from the exhaust manifold or turbocharger and their supply to subsequent elements of the exhaust system.

The exhaust system for cars and other equipment is a system of pipes and various elements that ensure the removal of hot gases from the engine into the atmosphere and reduce exhaust noise. When leaving the engine, the gases have a high temperature and pressure, so the most durable and heat-resistant element is located here - the exhaust manifold. Pipes with flame arresters, resonators, mufflers, neutralizers and other elements depart from the collector. However, in most systems, the installation of intake pipes is not carried out directly to the collector, but through an adapter element - a short intake pipe.

The intake pipe solves several problems in the exhaust system:

● Reception of exhaust gases from the manifold and their direction to the receiving pipe;

● Rotation of the exhaust gas flow at an angle that provides a convenient location of subsequent elements of the system;

● In the pipes with vibration compensators - vibration isolation of the engine and exhaust system.

The intake pipe is important for sealing the exhaust system and its normal functioning, therefore, in case of damage or burnout, this part needs to be replaced as soon as possible. And for the right choice of pipe, it is necessary to understand the existing types, design and features of these parts.

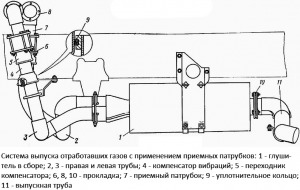

Exhaust system with the use of inlet pipes

Types and design of inlet pipes

It should be noted right away that intake pipes are not used in all engines - this part is more often found on units of trucks, tractors and various special equipment, and on passenger vehicles, receiving pipes of various configurations are more often used. Inlet pipes are convenient in the exhaust systems of powerful engines, where it is required to perform a simple removal of gases from the exhaust manifold or turbocharger in a confined space. So when repairing the system, you should first make sure that there is a pipe in it, or if you need a receiving pipe.

All intake pipes are divided into two large groups according to design and functionality:

● Conventional pipes;

● Nozzles combined with vibration compensators.

Simple pipes have the simplest design: it is a straight or bent steel pipe of variable cross-section, at both ends of which there are connecting flanges with holes for studs, bolts or other fasteners. Straight pipes can be made by stamping or from pipe segments, bent pipes are made by welding several blanks - side stamped walls and rings with flanges. Usually, mounting flanges are made in the form of rings or plates loosely put on the pipe, the pressure of the pipe to the mating parts (pipes, manifold, turbocharger) is provided by welded flanges of a smaller size. There are also nozzles without mounting flanges, they are mounted by welding or crimping by means of steel clamps.

Nozzles with expansion joints have a more complex design. The basis of the design is also a steel pipe, at the exhaust end of which there is a vibration compensator, which provides vibration isolation of the exhaust system parts. The compensator is usually welded to the pipe, this part can be of two types:

● Bellows - corrugated pipe (it can be one- and two-layer, can have an outer and inner braid made of stainless steel strips);

● A metal hose is a twisted metal pipe with an outer braid (it can also have an inner braid).

Pipes with expansion joints are also equipped with connecting flanges, but installation options are possible using welding or tie clamps.

Intake pipes can have a constant or variable cross-section. Expanding pipes are more often used, in which, due to a variable cross-section, there is a drop in the flow rate of the exhaust gases. Also, the parts may have a different profile:

● Straight pipe;

● Angle pipe with a bend of 30, 45 or 90 degrees.

Straight nozzles are used in systems where the bends necessary to turn the gas flow are provided in the exhaust manifold and/or in subsequent pipes. Angle pipes are most often used to turn the flow of gases vertically down or sideways and backwards relative to the engine. The use of angle pipes allows you to manufacture an exhaust system of the required configuration for convenient placement on the frame or under the car body.

Inlet pipe with bellows vibration compensator Inlet pipe with vibration

compensator in the form of a metal hose with a braid

Installation of intake pipes is carried out at two main points of the exhaust system:

● Between the exhaust manifold, compensator and intake pipe;

● Between the turbocharger, compensator and intake pipe.

In the first case, the exhaust gases from the collector enter the pipe, where they can rotate at an angle of 30-90 degrees, and then through the vibration compensator (separate bellows or metal hose) are fed into the pipe to the muffler (catalyst, flame arrester, etc.). In the second case, hot gases from the exhaust manifold first enter the turbine part of the turbocharger, where they partially give up their energy and only then are discharged to the intake pipe. This scheme is used on most cars and other automotive equipment with turbocharged engines.

In the cases described, the intake pipe is connected by its outlet side to the vibration compensator, made in the form of a separate part with its own flanges and fasteners. Such a system is less reliable and more susceptible to harmful vibrations, so today the most widely used pipes are integrated expansion joints. Their connection schemes are identical to those indicated above, but they do not have independent compensators and their fasteners.

Installation of pipes is carried out using studs or bolts passed through flanges. Sealing of joints is carried out by installing gaskets made of non-combustible materials.

How to choose and replace the intake pipe

The intake pipe of the exhaust system is subjected to significant thermal and mechanical loads, therefore, during the operation of the car, it is these parts that most often require replacement due to deformations, cracks and burnouts. Malfunctions of the pipes are manifested by an increased level of noise and vibrations of the exhaust system, and in some cases by a loss of engine power and a deterioration in the efficiency of the turbocharger (since the operating mode of the unit is disturbed). Pipes with cracks, burnouts and breakdowns (including malfunctions of integrated vibration compensators) must be changed.

For replacement, you should choose a pipe of the same type (catalog number) that was installed earlier. However, if necessary, you can use analogues, as long as they fully correspond to the original part in terms of installation dimensions and cross-section. If separate pipes and expansion joints were installed on the car, then it is better to use the same parts for replacement, however, if necessary, they can be replaced with pipes with an integrated compensator. Reverse replacement is also acceptable, but it can not always be performed, since in this case you will have to use additional fasteners and seals, for the placement of which there may not be free space.

Replacement of the pipe is carried out in accordance with the instructions for the repair of the vehicle. In general, this work is done simply: it is enough to disconnect the pipe (or compensator) from the pipe, and then remove the pipe itself from the manifold / turbocharger. However, these operations are often complicated by soured nuts or bolts, which must first be torn off with the help of special tools. When installing a new pipe, all the provided sealing elements (gaskets) should also be installed, otherwise the system will not be sealed.

With the correct selection and replacement of the intake pipe, the exhaust system will reliably perform its functions in all operating modes of the power unit.

Post time: Jul-14-2023