Alternator bar: fixing and adjusting the car's alternator

In cars, tractors, buses and other equipment, electric generators are mounted to the engine by means of a bracket and a tension bar that provides adjustment of the belt tension. Read about the generator strips, their existing types and design, as well as the selection and replacement of these parts in the article.

In cars, tractors, buses and other equipment, electric generators are mounted to the engine by means of a bracket and a tension bar that provides adjustment of the belt tension. Read about the generator strips, their existing types and design, as well as the selection and replacement of these parts in the article.

What is a generator bar

Generator bar (tension bar, adjustment bar) - an element of fastening the electric generator of vehicles; a steel bar with a curved hole or a system of two bars with bolts, designed to adjust the tension of the drive belt by changing the position of the generator.

The car electric generator is mounted directly on the engine block and is driven by a crankshaft by means of a belt drive. During the operation of the engine, wear and stretch of the belt, wear of pulleys and other parts occur, which can disrupt the operation of the generator - the stretched belt begins to slip and, in certain ranges of the crankshaft speed, does not transmit all the torque to the alternator pulley. To ensure the tension of the drive belt necessary for the normal operation of the generator, the generator is mounted on the engine through two supports - hinged and rigid with the possibility of adjustment. The basis of the adjustable support is one simple or composite part - the tension bar of the generator.

The generator bar, despite its extremely simple design, performs two key functions:

● The ability to deflect the generator at a certain angle around the hinge support in order to achieve the required belt tension;

● Fixing the generator in the selected position and preventing changes in this position due to dynamic loads (vibrations, uneven rotation of the belt, etc.).

The tension bar of the alternator is one of the most important elements that ensure the normal functioning of the entire electrical system of the car. Therefore, in case of breakage or deformation, this element must be replaced as soon as possible. But before buying a new bar, you should understand the existing types of these parts, their design and features.

Types and design of generator strips

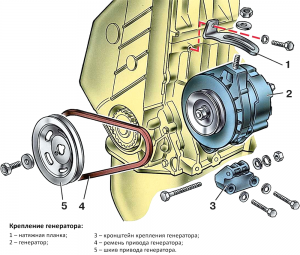

Generator mounting option with a simple tension bar

In modern automotive technology, generator strips of two main design types are used:

- Single planks;

- Composite strips with a belt tension adjustment mechanism.

Planks of the first type are the simplest and most reliable, so they still find the widest application. Structurally, this part is made in the form of a curved plate, in which there is a long oval hole for the mounting bolt. Such slats, in turn, are of two types:

- Longitudinal - they are arranged so that the axis of the mounting bolt is parallel to the axis of the generator shaft;

- Transverse - they are arranged so that the axis of the mounting bolt is perpendicular to the axis of the generator shaft.

A radius hole is made in the longitudinal strips, into which a mounting bolt is threaded, screwed into the corresponding threaded eye on the front cover of the generator.

There is also a long hole in the transverse strips, but it is straight, and the entire bar is brought into the radius. The mounting bolt is screwed into the transverse threaded hole made in the front cover of the generator at tide.

Strips of both types can be mounted directly on the engine block or on the bracket, for this purpose a conventional hole is made on them. The slats can be straight or L-shaped, in the second case, the hole for attaching to the engine is located on a short bent part.

Generator bar

Generator mounting option with a simple tension bar

Adjusting the position of the generator and, accordingly, the degree of tension of the belt using a single bar is quite simple: when the mounting bolt is loosened, the generator is removed from the engine at the required angle by hand force, and then the unit is fixed in this position with a mounting bolt. However, this method can lead to errors, since until the mounting bolt is tightened, the generator must be held by hand or improvised means. In addition, the single bar of the generator does not allow fine adjustment of the tension of the drive belt.

All these shortcomings are devoid of composite bars. These units consist of two main parts:

● Mounting bar mounted on the engine block;

● Tension bar mounted on the installation.

The installation bar is similar in design to a single one, but on its outer part there is another bend with a hole, which serves as an emphasis for the adjusting screw of the tension bar. The tension bar itself is a corner with threaded holes on each side, a thrust bolt is screwed into one hole (usually of a smaller diameter), and a mounting bolt is screwed into the other (of a larger diameter). Installation of the composite tension bar is carried out as follows: an installation bar is located on the engine block, a tension bar mounting block is screwed into its hole and into the corresponding threaded hole in the generator, and an adjusting (tension) bolt is screwed into the second threaded hole of the tension bar through the outer hole of the installation bar. This design allows you to set the required tension of the alternator belt by rotating the adjusting bolt, which prevents errors that occur when adjusting the tension of the alternator belt with single strips.

All types of adjustment strips (single and composite) are made by stamping from sheet steel of such a thickness that ensures high strength and rigidity of the part. Additionally, the strips can be painted or have chemical or galvanic coatings to protect against the destructive effects of negative environmental factors. The slats can be located both at the top and at the bottom of the generator - it all depends on the design of a particular vehicle.

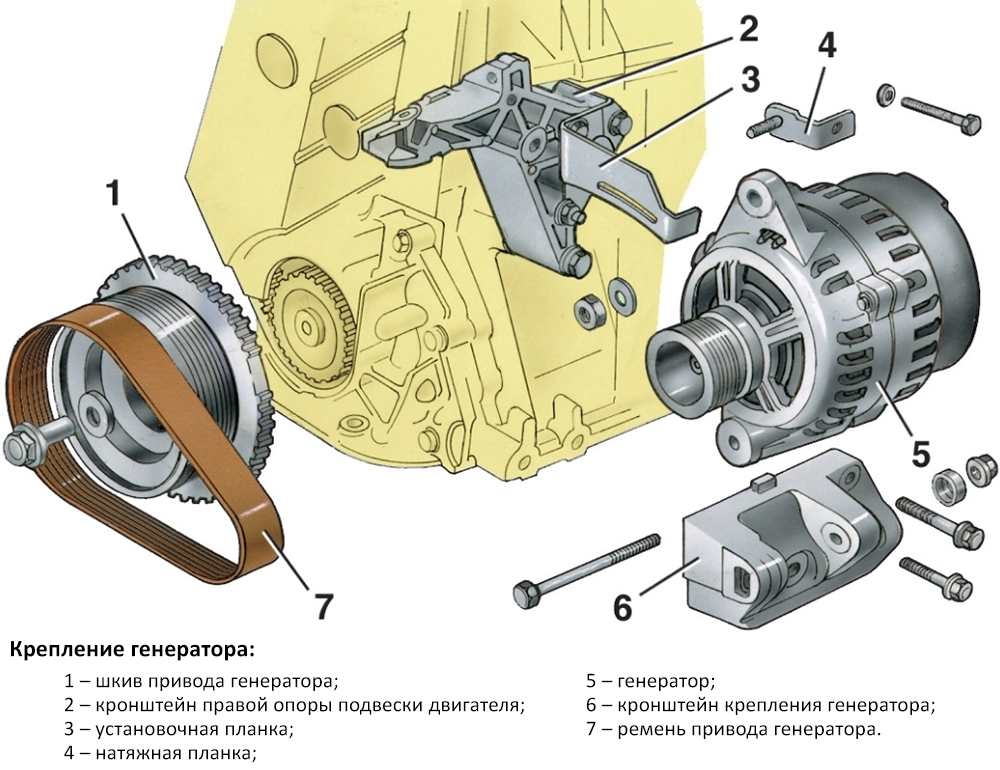

composite generator bar assembly

Variant of mounting the generator with tension and installation strips

How to choose, replace and repair a generator bar

The generator bar during the operation of the car can be deformed and even completely destroyed, which requires its immediate replacement. For replacement, you should take a bar of the same type and catalog number that was used on the car earlier. In some cases, it is possible to replace it with an analogue that is suitable in size, but it should be borne in mind that a "non-native" part may not provide the required range of belt tension adjustments and have insufficient mechanical strength.

As a rule, replacing the alternator bar and adjusting the belt tension is not difficult, this work comes down to unscrewing two bolts (mounting from the generator and from the unit), installing a new part and screwing in two bolts with simultaneous adjustment of the belt tension. These operations should be performed in accordance with the repair instructions for this particular vehicle. It should be borne in mind that generators with a single bar are more difficult to adjust, since there is always a risk of displacement of the unit relative to the bar until the bolt is completely screwed in. Changing the position of the alternator with a composite bar is reduced to screwing in the adjusting bolt until the required degree of belt tension is reached.

With the right choice and replacement of the bar, the generator will function reliably, confidently providing energy to the on-board power grid in all engine operating modes.

Post time: Jul-10-2023