The basis for controlling the injection engine is the throttle assembly, which regulates the flow of air into the cylinders. At idle, the air supply function goes to another unit - the idle speed regulator. Read about regulators, their types, design and operation, as well as their selection and replacement in the article.

What is an idle speed regulator?

Idle speed regulator (XXX, additional air regulator, idle sensor, DXH) is the regulating mechanism of the power supply system for injection engines; An electromechanical device based on a stepper motor that provides metered air supply to the motor receiver bypassing the closed throttle valve.

In an internal combustion engine with a fuel injection system (injectors), speed control is carried out by supplying the required volume of air to the combustion chambers (or rather, to the receiver) through the throttle assembly, in which the throttle valve controlled by the gas pedal is located. However, in this design, there is a problem of idling - when the pedal is not pressed, the throttle valve is completely closed and air does not flow to the combustion chambers. To solve this problem, a special mechanism is introduced into the throttle assembly that provides air supply when the damper is closed - an idle speed regulator.

XXX performs several functions:

● Supply of air necessary for starting and warming up the power unit;

● Adjustment and stabilization of the minimum engine speed (idling);

● Damping of the air flow in transient modes - with a sharp opening and closing of the throttle valve;

● Adjustment of the motor operation in various modes.

The idle speed regulator mounted on the throttle assembly body ensures normal operation of the engine at idle and at partial load modes. The failure of this part disrupts the functioning of the motor or completely disables it. If a malfunction is detected, the RHX should be replaced as soon as possible, but before buying a new part, it is necessary to understand the design and operation of this unit.

The throttle assembly and the place of the RHX in it

Types, design and principle of operation of PHX

All idle regulators consist of three main components: a stepper motor, a valve assembly, and a valve actuator. The PX is mounted in a special channel (bypass, bypass), located bypassing the throttle valve, and its valve assembly controls the passage of this channel (adjusts its diameter from full closure to full opening) - this is how the air supply to the receiver and further to the cylinders is adjusted.

Structurally, PXX can differ significantly, today three types of these devices are used:

● Axial (axial) with a conical valve and with a direct drive;

● Radial (L-shaped) with a conical or T-shaped valve with a drive through a worm gear;

● With a sector valve (butterfly valve) with a direct drive.

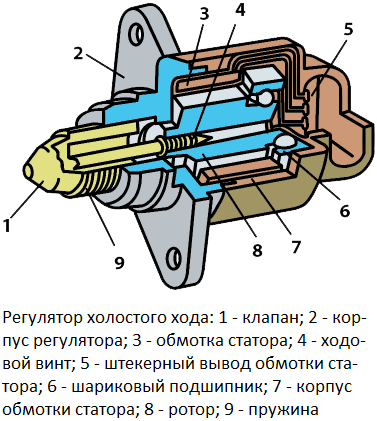

Axial PXX with a conical valve are most widely used in passenger cars with small engines (up to 2 liters). The basis of the design is a stepper motor, along the axis of the rotor of which a thread is cut - a lead screw is screwed into this thread, acting as a rod, and carrying a cone valve. The lead screw with the rotor makes up the valve actuator - when the rotor rotates, the stem extends or retracts with the valve. This whole structure is enclosed in a plastic or metal case with a flange for mounting on the throttle assembly (installation can be done with screws or bolts, but varnish mounting is often used - the regulator is simply glued to the throttle assembly body with a special varnish). On the back of the case there is a standard electrical connector for connecting to the electronic engine control unit (ECU) and supplying power.

No-load regulator with direct valve stem drive

It should be noted that in steering trapezoids for an axle with independent suspension, one tie rod is actually used, divided into three parts - it is called a dismembered rod. The use of a dismembered tie rod prevents spontaneous deflection of the steered wheels when driving on bumps in the road due to different amplitude of oscillation of the right and left wheels. The trapezoid itself can be located in front and behind the axle of the wheels, in the first case it is called the front, in the second - the rear (so do not think that the "rear steering trapezoid" is a steering gear located on the rear axle of the car).

In steering systems based on the steering rack, only two rods are used - right and left transverse to drive the right and left wheels, respectively. In fact, this is a steering trapezoid with a dissected longitudinal rod with a hinge at the midpoint - this solution greatly simplifies the design of the steering, increasing its reliability. The rods of this mechanism always have a composite design, their outer parts are usually called steering tips.

Tie rods can be divided into two groups according to the possibility of changing their length:

● Unregulated - one-piece rods that have a given length, they are used in drives with other adjustable rods or other parts;

● Adjustable - composite rods, which, due to certain parts, can change their length within certain limits to adjust the steering gear.

Finally, rods can be divided into many groups according to their applicability - for cars and trucks, for vehicles with and without power steering, etc.

Radial (L-shaped) PXX have about the same application, but can work with more powerful engines. They are also based on a stepper motor, but on the axis of its rotor (armature) there is a worm, which, together with the counter gear, rotates the torque flow by 90 degrees. A stem drive is connected to the gear, which ensures the extension or retraction of the valve. This entire structure is located in an L-shaped housing with mounting elements and a standard electrical connector for connecting to the ECU.

PXX with a sector valve (damper) is used on engines of a relatively large volume of cars, SUVs and commercial trucks. The basis of the device is a stepper motor with a fixed armature, around which a stator with permanent magnets can rotate. The stator is made in the form of a glass, it is installed in the bearing and is directly connected to the sector flap - a plate that blocks the window between the inlet and outlet pipes. The RHX of this design is made in the same case with the pipes, which are connected to the throttle assembly and the receiver by means of hoses. Also on the case is a standard electrical connector.

Despite the design differences, all PHX have a fundamentally similar principle of operation. At the moment the ignition is turned on (immediately before starting the engine), a signal is received from the ECU to the RX to completely close the valve - this is how the zero point of the regulator is set, from which the value of the bypass channel opening is then measured. The zero point is set in order to correct the possible wear of the valve and its seat, the monitoring of the complete closure of the valve is carried out by the current in the PXX circuit (when the valve is placed in the seat, the current increases) or by other sensors. The ECU then sends pulse signals to the PX stepper motor, which rotates at one angle or another to open the valve. The degree of opening of the valve is calculated in the steps of the electric motor, their number depends on the design of the XXX and the algorithms embedded in the ECU. Usually, when starting the engine and on an unheated engine, the valve is open at 240-250 steps, and on a warm engine, valves of various models open at 50-120 steps (that is, up to 45-50% of the channel cross-section). At various transient modes and at partial engine loads, the valve can open in the entire range from 0 to 240-250 steps.

That is, at the time of starting the engine, the RHX provides the necessary volume of air to the receiver for normal engine idling (at speeds less than 1000 rpm) in order to warm it up and enter normal mode. Then, when the driver controls the engine using the accelerator (gas pedal), the PHX reduces the amount of air entering the bypass channel until it is completely shut off. The engine ECU constantly monitors the position of the throttle valve, the amount of incoming air, the concentration of oxygen in the exhaust gases, the speed of the crankshaft and other characteristics, and based on these data controls the idle speed regulator, in all engine operating modes ensuring the optimal composition of the combustible mixture.

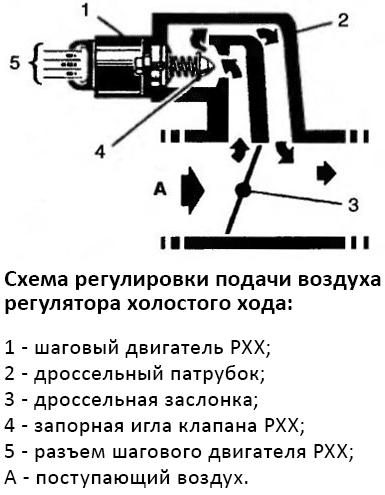

Circuit of adjustment of the air supply by the idle speed regulator

Issues of selection and replacement of the idle speed regulator

Problems with the XXX are manifested by the characteristic operation of the power unit - unstable idle speed or spontaneous stop at low speeds, the ability to start the engine only with frequent pressing of the gas pedal, as well as increased idle speed on a warm engine. If such signs appear, the regulator should be diagnosed in accordance with the vehicle repair instructions.

On cars without the XXX self-diagnostic system, you should perform a manual check of the regulator and its power circuits - this is done using a conventional tester. To check the power circuit, it is necessary to measure the voltage across the sensor when the ignition is on, and to check the sensor itself, you need to dial the windings of its electric motor. On vehicles with an XXX diagnostic system, it is necessary to read error codes using a scanner or computer. In any case, if a malfunction of the RHX is detected, it must be replaced.

Only those regulators that can work with this specific throttle assembly and ECU should be selected for replacement. The required PHX is selected by catalog number. In some cases, it is quite possible to use analogues, but it is better not to carry out such experiments with cars under warranty.

Replacement of the PXX is carried out in accordance with the instructions for repairing the car. Usually, this operation comes down to several steps:

1.De-energize the electrical system of the car;

2.Remove the electrical connector from the regulator;

3.Dismantle the RHX by unscrewing two or more screws (bolts);

4.Clean the installation site of the regulator;

5.Install and connect a new PXX, while you need to use the included sealing elements (rubber rings or gaskets).

In some cars, it may additionally be necessary to dismantle other elements - pipes, air filter housing, etc.

If the RHX was installed on the car with varnish, then you will have to remove the entire throttle assembly, and put the new regulator on a special varnish purchased separately. For the installation of devices with a sector damper, it is recommended to use new clamps to fix the hoses on the pipes.

With the right choice and installation, the RHX will start working immediately, ensuring the normal functioning of the engine in all modes.

Post time: Jul-26-2023