In accordance with the current rules, when the car is reversing, a special white light must burn. The operation of the fire is controlled by a reversing switch built into the gearbox. This device, its design and functioning, as well as its selection and replacement are described in the article.

Purpose and role of the reversing switch

Reversing switch (VZH, flashlight/reversing light switch, reversing sensor, jarg. "frog") - a button-type switching device built into the gearbox of transmissions with manual control (mechanical gearboxes); limit switch of a special design, which is entrusted with the functions of automatic switching of the electrical circuit of the reversing lamp when the reverse gear is turned on and off.

The VZX is located directly in the gearbox and is in contact with moving parts. This device has the following functions:

- Closing the reversing light circuit when the lever is moved to the "R" position;

- Opening the reversing light circuit when the lever is transferred from position "R" to any other;

- In some vehicles and various machines - switching circuits of an auxiliary sound alarm that warns of reversing (turning on a buzzer or other device that makes a characteristic sound, and sometimes additional lights).

VZKh is an important component of the vehicle's light signaling system, if it malfunctions or refuses, an administrative penalty in the form of a fine may be imposed on the driver. Therefore, a faulty switch must be replaced, but before you go to an auto parts store, you should understand the design, operation and characteristics of these parts.

Types, design and principle of operation of the reversing switch

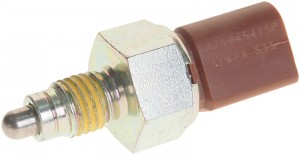

The currently used reversing switches have a fundamentally identical design, differing only in some details and characteristics. The basis of the device is a metal case made of bronze, steel or other corrosion-resistant alloys. The body has a turnkey hexagon and a thread for mounting in the gearbox crankcase. There is a button on the thread side, a contact group connected to the button is installed inside the case, and the back of the case is covered with a plastic cover with terminals. Also, a second thread of increased diameter can be made on the housing on the terminal side, used to connect other components.

VZX buttons can be of two design types:

● Spherical (short-stroke);

● Cylindrical (long-stroke);

In devices of the first type, a ball made of steel or other metals, partially recessed in the body, usually such a button has a stroke of no more than 2 mm. In devices of the second type, a metal or plastic cylinder (from 5 to 30 mm or more in length) acts as a button, usually its stroke reaches 4-5 mm or more. A button of any type is located in the protrusion of the metal body of the switch, it is rigidly connected to the movable contact of the contact group. The button is spring-loaded, which ensures that the chain opens when reverse gear is disengaged.

Spherical button switch

Switch with cylindrical button

The switch is connected to the vehicle's mains supply by a standard connector (both conventional and bayonet - swivel) with knife / pin contacts, using screw clamps or single pin / knife terminals. Devices with connectors of the first type are connected to standardized blocks, wires with removed insulation are connected to devices of the second type, and single mating terminals of the "mother" type are connected to devices of the third type. There are also VZKhS with electrical connectors placed on the wiring harness.

Of the main characteristics of VZKh, it should be noted:

● Supply voltage - 12 or 24 volts;

● Rated current - usually no more than 2 amperes;

● Thread size - the most widespread series M12, M14, M16 with a thread pitch of 1.5 mm (less often - 1 mm);

● Turnkey sizes are 19, 21, 22 and 24 mm.

Finally, all VZKh can be divided into groups according to applicability - specialized and universal. In the first case, the switch is mounted only on the gearbox and serves to switch the reversing light circuit (as well as the corresponding sound alarm). In the second case, the switch can be used to switch various circuits - reversing lights, brake lights, divider and others.

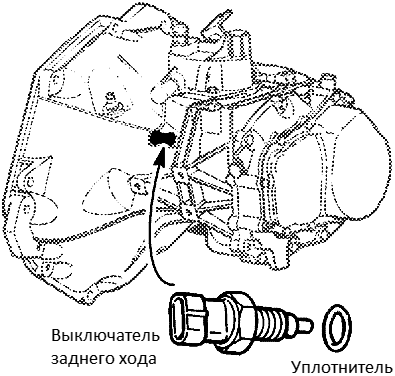

Installing the reverse switch on the gearbox through the O-ring

The VZX is screwed into the threaded hole provided for it, made in the gearbox crankcase, the seal connection is made using a metal washer, rubber or silicone ring. The switch button is located in the cavity of the gearbox crankcase, it is in contact with the moving parts of the gear selection mechanism - most often with the reverse fork rod. When the reverse gear is turned off, the fork stem is at some distance from the switch, due to the force of the spring, the button is extended from the housing, the contact group is open - no current flows through the circuit of the reversing lamp and the lamp does not burn. When reverse gear is engaged, the fork stem rests against the button, it is recessed and leads to the closure of the contacts - current begins to flow through the circuit and the flashlight lights up. Thus, the reversing switch works like a simple push-button switch without locking positions, but its design provides resistance to gear oil, high pressures, temperatures and mechanical stress.

Issues of selection and repair of reversing switches

As we pointed out earlier, a non-working or incorrectly functioning VZH can cause a fine. The fact is that the presence and operation of a reversing lamp on all vehicles are regulated by domestic and international standards (in particular, GOST R 41.48-2004, UNECE Rules No. 48, and others), and paragraph 3.3 of the "List of malfunctions and conditions under which the operation of the vehicle is prohibited" indicates the impossibility of operating the car with incorrectly working or completely non-working lights. That is why a faulty reversing switch should be changed as soon as possible after detecting its malfunction.

There are two main types of circuit breaker faults – contact loss in the contact group and short circuit in the contact group. In the first case, the lamp does not light up when reverse gear is engaged, in the second case, the lamp is always on or periodically when reverse gear is turned off. In any case, the switch must be checked with a tester or a simple probe, and if a malfunction is detected, replace the device (due to the design features, it makes no sense to repair the switch - it is easier and cheaper to completely replace it).

To successfully complete the repair, it is necessary to take a switch of the same type and model (catalog number) that was installed in the box by its manufacturer - this is the only way to guarantee the normal operation of the entire system. If for some reason it was not possible to find the right switch, you can try to choose an analogue that corresponds to the electrical characteristics (for a voltage of 12 or 24 volts), installation dimensions (thread parameters, body dimensions, type and dimensions of the button, etc.), type of electrical connector, etc.

Work on replacing switches is quite simple, although they have their own characteristics. In particular, the replacement of the device must be done as soon as possible, since when dismantling the old switch from the gearbox, oil leaks (not in all boxes). Also, when installing a new switch, you need to take care of the O-ring, otherwise there will be constant loss of oil, which is fraught with damage to the gearbox. If you follow the vehicle repair instructions and these recommendations, the switch will be replaced quickly and without negative consequences - coupled with the right choice of a new part, this will ensure reliable operation of the reversing light.

Post time: Jul-13-2023