In engines with overhead valves and other timing devices, a cover is provided, which is installed on the cylinder head through a gasket. Read about what a valve cover gasket is, what types it is and how it works, as well as its correct choice and replacement, read the article

What is a valve cover gasket?

Valve cover gasket (cylinder head cover gasket) is a sealing element of reciprocating internal combustion engines with overhead valves of the gas distribution mechanism; Elastic gasket for sealing the volume covered by the cylinder head cover installed on the cylinder head.

The cylinder head cover gasket performs several functions:

- Ensuring the tightness of the lid to the head;

- Sealing the volume covered by the lid to prevent oil leakage;

- Protection of valve parts and oil from contamination (from dirt, dust, exhaust gases, etc.).

The gasket of the valve cover is not a critical part for the operation of the engine - without it, the power unit will function completely. However, it ensures the cleanliness of the engine, its fire safety (preventing oil leaks and getting it on heated parts - the exhaust manifold and others) and ease of maintenance. In addition, the gasket contributes to maintaining the cleanliness and characteristics of the engine oil. Therefore, if leaks appear from under the cover, the gasket should be replaced, and in order to make the right choice, you should understand the types, features and characteristics of these parts.

Types, design and characteristics of valve cover gaskets

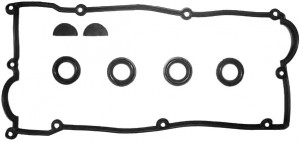

Regardless of the type, all valve cover gaskets have the same device in principle. This is a flat elastic part that repeats the shape of the plane of adhesion of the cover to the cylinder head, and has holes for fasteners and other parts. The gasket is placed under the cover, and due to its elasticity, it seals the gap between the lid and the cylinder head (filling in micro-irregularities and compensating for small deviations of their butt surfaces from the plane), ensuring its sealing.

In this case, the gaskets can have a different design:

● Whole (non-discontinuous) - an annular gasket or a gasket of a more complex shape (for example, under the covers of engines with two camshafts on the cylinder head) without breaks, which is simply installed under the cover;

● Composite - a gasket with gaps and inserts for sealing the camshaft inlet or other parts;

● Complete - in addition to the main gasket, the kit may include additional O-ring seals for candle wells and other holes in the lid.

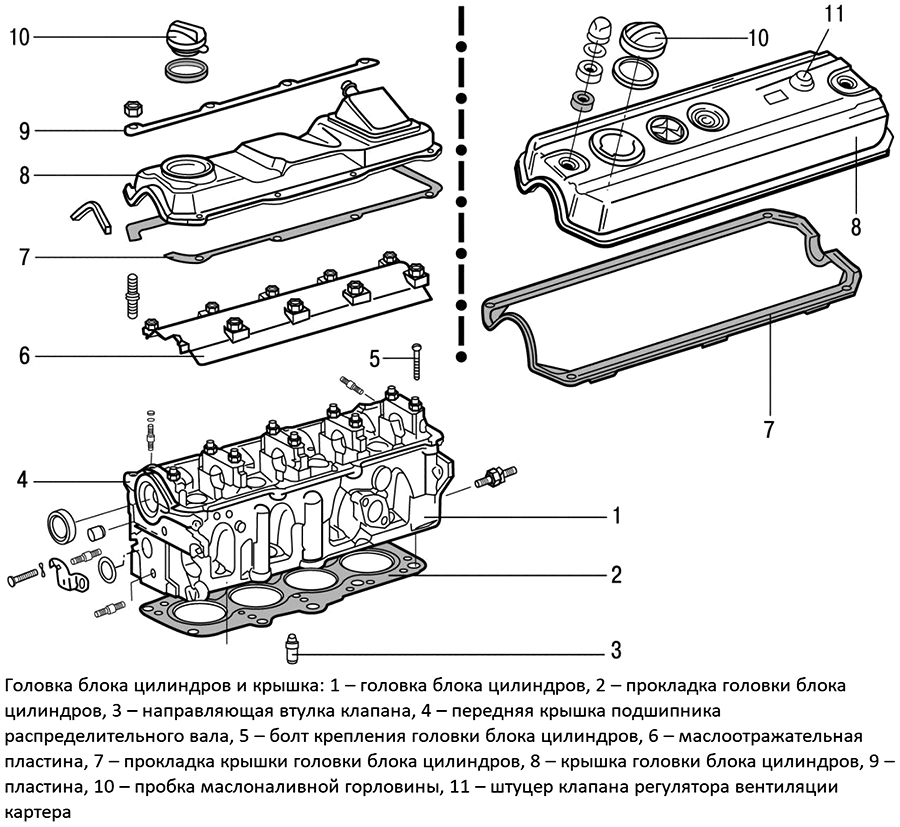

Valve cover with gasket and their place in the power unit

Valve cover gaskets can be divided into several types according to the material of manufacture and applicability with different types of cylinder head.

According to the material of manufacture of gaskets are:

● Rubber;

● Rubber-cork;

● Paronite;

● Cardboard.

The first type of products are made on the basis of heat-resistant and oil-resistant rubber, which is modified with additives and subsequent vulcanization.

Rubber gasket valve cover

The rubber gasket is made from various grades of rubber, it is the most elastic, however, due to the shortcomings of the material of manufacture, it can significantly change its characteristics during temperature changes (soften at high temperatures, become less elastic in the cold) and generally has less durability.

Rubber cork gaskets are made on the basis of rubber, to which granular cork or other porous fillers are added. Such material provides a high degree of sealing and vibration isolation, but gaskets made of it are very demanding on the quality of installation and installation of the cover, they often require additional treatment with liquid sealant and have a limited service life.

Rubber plug gasket valve cover

Paronite gaskets are made of paronite, a rubber-based material with various mineral additives, which is further molded and vulcanized. Paronite can be asbestos and asbestos-free, but today manufacturers are abandoning the use of asbestos in favor of safer materials. Also, paronite gaskets can be ordinary unreinforced and reinforced with steel wire, thin perforated tin, etc. It is the paronite gaskets of cylinder head covers that are most widely used today due to their high reliability, resistance to negative influences and good sealing qualities.

Cardboard pads are made of special grades of thick paper that have been processed to gain resistance to oils, gasoline, water and other negative influences. These gaskets are the cheapest, but they are the least reliable, so today they are used on the simplest engines.

According to the applicability of the gasket of valve covers, it can be divided into two groups:

● For general cylinder heads - in in-line and V-shaped engines with a common head and cover for all or one row of cylinders;

● For separate cylinder heads - in engines with individual heads and covers for each cylinder.

Structurally, gaskets for common and separate heads do not differ, they only have different sizes for the corresponding covers.

cylinder head cover gaskets are manufactured according to the standards of automakers, and they can also comply with domestic standards GOST 481-80, GOST 15180-86 and others.

Issues of selection and replacement of the valve cover gasket

The valve cover gasket is an important part, but it is short-lived and often requires replacement. Usually, gasket replacement is performed in the following situations:

● The appearance of oil leaks from under the lid (this indicates damage or destruction of the gasket due to mechanical and chemical influences, or as a result of natural aging processes);

● With each repair of the gas distribution mechanism;

● In case of overhaul of the power unit or replacement of its individual parts or assemblies - cylinder head, valve covers and others;

● With routine maintenance, if it is provided by the engine manufacturer.

For replacement, you should choose a gasket designed for this particular brand and model of the power unit, since parts for other motors simply will not fit in size and configuration. However, there are options for choosing the material for the manufacture of the gasket. For new cars under warranty, it is necessary to use a gasket made of the material specified by the manufacturer, in this case, the replacement of the part should be trusted only to specialists.

For other cars, you can choose a gasket made of rubber, paronite or rubber stopper - in principle, modern gaskets are standardized in terms of characteristics, so they all have approximately the same characteristics. True, here you need to remember about the strength qualities and ease of installation of gaskets made of various materials. For example, paronite gaskets are the most rigid, so they are the easiest to install, and rubber cork products, on the contrary, are easily deformed and torn, so their installation is the most difficult and requires special care.

Replacement of the cylinder head cover gasket must be carried out in accordance with the vehicle repair instructions. Usually, this work boils down to the following:

1.Dismantle equipment that impedes access to the valve cover - remove the filter, remove various pipes;

2.Remove the cover, remove the old gasket, clean the filler surfaces of the cover and cylinder head;

3.Install a new gasket;

4.Install the cover, tighten the bolts in the correct order - crosswise from the center to the edges.

For the installation of some types of gaskets, it may be necessary to degrease the surfaces of the cylinder head and the cover, and after installation, introduce sealant in some places (or treat the joint of parts with it) - this is specifically indicated in the instructions. With the right choice and replacement of the gasket, when it is installed without distortions in the tightening of the bolts and without other errors, the volume under the cover will be reliably sealed, so the engine will remain clean, and the valve mechanism will be protected from various negative influences.

Post time: Jul-26-2023