n the suspensions of trucks, buses and other equipment, there are elements that compensate for the reactive moment - jet rods. The connection of the rods with the beams of the bridges and the frame is carried out with the help of fingers - read about these parts, their types and design, as well as the replacement of fingers in the article.

What is a reaction rod finger

The pin of the jet rod is a component of the suspension of trucks, buses, semi-trailers and other equipment; part in the form of a finger or finger with a rubber-metal hinge, which is the axis of the hinge connection of the rod with the frame and beam of the bridge.

In trucks, buses and semi-trailers, a dependent suspension of the spring and spring-balance type is used, which, with a relatively simple design and high reliability, has some drawbacks. One of these drawbacks is the need to compensate for reactive and braking torques that occur when the car is moving. The reactive moment occurs when the wheels of the drive axle rotate, this moment tends to twist the axle in the opposite direction, which leads to deformation of the springs and the appearance of unbalanced forces in various suspension units. The braking torque acts similarly, but has the opposite direction. To compensate for the reactive and braking torque, as well as to ensure the connection of the axles or the trolley with the frame without losing the ability to move the suspension parts in the vertical plane, additional elements are introduced into the suspension - jet rods.

Jet rods are mounted to the axle beams and brackets on the frames with the help of hinges that provide the ability to rotate the rods relative to the beams and the frame when changing the position of the suspension parts at the moments of overcoming road irregularities, when picking up speed and braking. The basis of the hinges are special parts - the fingers of the jet rods.

The finger of the reaction rod performs several functions:

● Mechanical connection of the rod with the suspension parts and the frame of the vehicle;

● It acts as the axis of the swivel joint, relative to which the rod rotates;

● In rods with rubber-metal hinges - damping shocks and vibrations, preventing their transfer from the suspension to the frame and in the opposite direction.

The pin of the reaction rod is an important element of the suspension, so if it wears, deforms or breaks, it must be replaced. But for a confident repair, you need to know what the fingers are, how they are arranged, how they differ from each other, and how to choose them correctly.

Types, design and features of the pin of the reaction rod

First of all, the fingers of the jet rods are divided into two large groups according to the method of installation and fastening:

● Ball single-support pins;

● Two-support fingers.

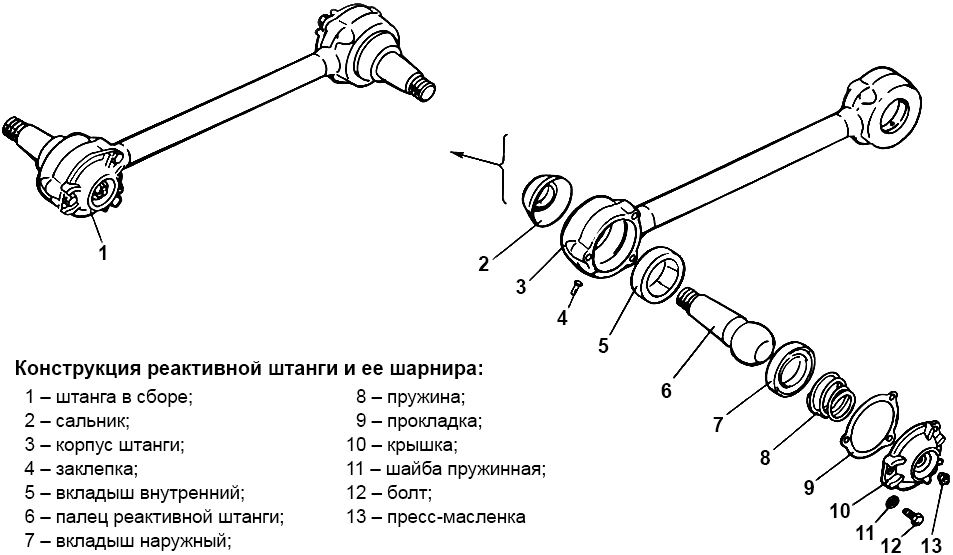

Parts of the first type are standard fingers made in the form of a conical rod with a ball at one end and a thread at the other. The spherical part of such a pin is mounted in the rod, and the rod enters the hole in the bracket of the frame or beam of the bridge. The installation of the finger in the rod is carried out between two ring steel liners (breadcrumbs) with hemispherical internal parts in which the finger ball rotates freely. The rod part of the pin comes out of the rod through the oil seal, the finger is fixed using a bolted cover, an oiler is installed in the same cover to fill the hinge with grease. In some rods, a support conical spring is located between the pin and the cover, which ensures the correct position of the parts.

Ball single-bearing pins are divided into two types:

● Standard steel ("bare");

● With integrated rubber-metal hinge (RMS).

The design of the reaction rod and its hinge

The design of the finger of the first type is described above, the fingers of the second type are arranged similarly, however, a rubber-metal hinge is located in them from the side of the installation in the rod, which provides damping of shocks and vibrations. RMS is made in the form of a ring made of dense rubber or polyurethane, which encircles the inside of the finger with an extension. Additionally, the RMS can be fixed with a metal ring.

It is interesting to note that today the fingers of jet rods "with a double resource" are offered - at the heart of such parts is an ordinary ball pin, on the spherical part of which there is a rubber-metal hinge. After the rubber (or polyurethane) ring is worn, the finger is removed, the remnants of the RMS are removed from it, and in this form the part is re-installed in the rod through the liners. A finger of this type seems attractive to buy, but the quality of such products is not always high, and for their timely replacement it is necessary to regularly inspect the suspension and not miss the moment when the RMS is worn out, and the spherical part of the finger has not yet had contact with the barbell. In addition, a set of additional parts is required to reinstall the finger, which increases repair costs.

Also, ball single-support pins are divided into two types according to the method of fixing the nut from the side of the bridge beam bracket or frame:

● Fixing with cotter pin;

● Fixing with a grower.

Reaction rod pin with rubber-metal hinge

In the first case, a crown nut is used, which, after tightening, is blocked by a cotter pin passed through a transverse hole in the threaded part of the pin. In the second case, the nut is fixed with a grower (spring split washer), which is placed under the nut. There is no hole in the finger for the grower on the side of the thread.

Double-bearing pins are rods, in the central expanded part of which there is a rubber-metal hinge. Such a finger has transverse holes on both sides, or a through hole on one side, and a blind channel on the other. The finger is installed in the rod, fixed with retaining rings and covers, an O-ring can be located between the retaining ring and the RMS. Jet rods can have only one or two double-supporting fingers at once, the fastening of such fingers to the frame or beam is carried out using special brackets with counter threaded rods (fingers) and nuts.

The finger of the reaction rod is two-support with a rubber-metal hingeD

The pins of the jet rods are made of high-quality and high-quality structural carbon and medium carbon steels of grades 45, 58 (55pp) and similar, as well as alloy structural steels 45X and similar. The spherical part of the pin is quenched with high-frequency currents to a depth of 4 mm, which ensures an increase in hardness (up to 56-62 HRC) and wear resistance of the part. The internal parts of steel liners used in conjunction with standard ball pins are also quenched to similar hardness values - this ensures high resistance to wear of the entire hinge.

How to choose and replace the pin of the reaction rod

The fingers of the reaction rods and the parts associated with them are constantly subjected to high loads, which gradually leads to wear, and with strong blows, the finger can be deformed or destroyed. The need to replace the fingers is indicated by the increased backlash in the ball joint, as well as visually detectable mechanical damage. In these cases, the finger must be replaced, and it is recommended to change the mating parts - inserts (crackers) of ordinary ball pins, springs, seals.

Only those types and catalog numbers recommended by the manufacturer of the vehicle or suspension should be taken for replacement. However, in some cases, it is possible to replace a conventional ball pin with a single-support RMS pin with the corresponding removal of crackers and other components. The most convenient solution for repairs is complete repair kits, which, in addition to the finger itself, include crackers, O-rings and retaining rings, springs and other components.

Finger replacement must be carried out in accordance with the repair instructions for a particular car, bus or semi-trailer. Usually, the work comes down to dismantling the entire rod, disassembling it, cleaning it, installing a new pin and mounting the assembled rod on the suspension. As a rule, two to four nuts need to be unscrewed to remove one rod, and in the case of a conventional ball pin, pre-pinning may be required. Problems may arise at the stage of dismantling the rod, as the parts turn sour or jam due to deformations, and disassembly will require considerable effort. And in some cases, it is necessary to use special pullers.

Reaction rod complete with fingers

Reaction rod with double-bearing pins

After installing new ball pins, it is required to fill the rod with grease through an oiler, and the types of lubricants recommended by the manufacturer should be used (usually Litol-24, solidol and similar, it is best to be guided by the chemical map of the car's lubrication). In the future, fresh grease is refilled with each seasonal maintenance.

The rod assembly with pins is installed in the suspension using one or another method of fixing the nut - cotter pin or grower. The purchase of these parts, if they do not come as part of the repair kit, should be taken care of in advance.

The correct selection of the pin and its replacement, as well as regular maintenance of the hinges of the reaction rods is one of the foundations of reliable and safe operation of the entire suspension of a truck, bus, semi-trailer and other equipment.

Post time: Jul-11-2023