The shafts coming out of the transmission units and other mechanisms of the car can cause leakage and contamination of the oil - this problem is solved by installing oil seals. Read all about drive oil seals, their classification, design and applicability, as well as the correct choice and replacement of seals in the article.

What is an actuator oil seal?

The drive oil seal (cuff) is a sealing element of various units and systems of vehicles; An annular component that seals shafts, bearings and other rotating parts at their exit points from the unit housing.

In any car, tractor and other equipment there are units and mechanisms, from the body of which rotating shafts come out - gearboxes, gearboxes, fan drives and others. Usually, there is oil or other grease inside these units, and the shaft hole can cause loss and contamination of the lubricant. The task of sealing the output of rotating shafts outside the housings of the units is solved with the help of special sealing elements - oil seals (cuffs) of the drive.

The drive oil seal performs several functions:

● Prevention of oil leakage and loss of other lubricant from the body of the unit or mechanism;

● Protection of the mechanism from the ingress of water, dust and large contaminants;

● Protection of lubricant from contamination by exhaust and other gases.

Violation of the integrity or loss of the oil seal leads to significant oil leakage and contamination, which in the very near future can cause damage to the entire unit. To prevent this, an exhausted or faulty drive oil seal must be replaced in a timely manner. For the correct selection and replacement of sealing elements, it is necessary to understand their existing types, design and applicability.

Types, design and features of drive oil seals

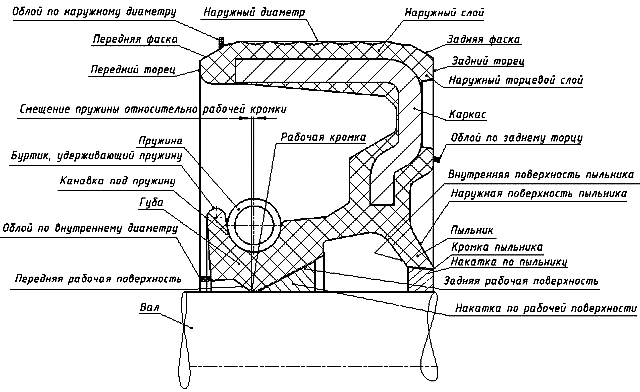

All oil seals are made in the form of a ring with a U-shaped profile, in which three surfaces stand out:

● Internal or working - consists of working edges, the oil seal rests on the shaft with this surface;

● Outer - smooth or corrugated, this surface of the oil seal is in contact with the body of the unit;

● End - usually flat, this surface is parallel to the body of the unit.

The cuff is installed in the seat in the body of the unit (stuffing box) and rests on the shaft, due to the design, its tight pressure to the body and shaft is ensured, which achieves sealing.

Oil seals are divided into several types according to the presence / absence of various elements and features of work.

First of all, oil seals are divided into two types according to their design:

● Frameless;

● With reinforcing frame.

Oil seals of the first type are made in the form of an elastic ring made of synthetic rubber, on the inner surface of which the working edges are formed. As standard, there are two working edges in the oil seals - front and rear, but their number can reach four. Inside the ring there is a coiled spring rolled into a ring, which provides a tight pressure of the oil seal to the shaft.

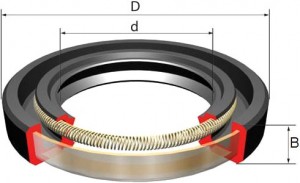

Oil seals of the second type are more complicated - inside the ring there is a steel reinforcing frame of one shape or another. Most often, the frame has a straight (plate rolled into a ring) or L-shaped profile, but there are oil seals with frames of a more complex profile. The rest of the reinforced parts are similar to the non-reinforced ones.

Oil seals with a reinforcing frame are divided into three structural types:

● With closed frame;

● With a partially bare frame;

● With a bare frame.

In the design of the first type, the frame is completely located inside the rubber ring of the oil seal, or the ring completely covers only the outer surface of the frame. In the second case, the ring covers the end and part of the outer surface of the frame, and in the third, the frame is almost completely open. Oil seals with a partially and completely bare reinforcing frame are more firmly installed in their seat, since they rest against the metal body of the unit with a metal ring. Although such oil seals provide a worse seal, which forces the use of sealants or additional parts

Typical design of the drive oil seal

The design of the unreinforced oill seal with a spring

The design and main dimensions of the reinforced oill seal with a spring

The elastic ring of all types of oil seals can be made of various types of synthetic rubber - acrylate, fluororubber, nitrile butadiene, silicone (organosilicon) and others. These materials have unequal resistance to high and low temperatures and lubricants, but they have approximately the same coefficients of friction on steel and mechanical strength.

Drive oil seals can have various additional elements:

● The anther is a small protrusion in the front of the ring that prevents large contaminants (stones, threads, chips, etc.) from entering the oil seal. The boot can be pressed against the shaft due to its own elasticity or with the help of an additional twisted spring;

● Outer surface corrugation - corrugation of simple or complex shapes, which improves the fit of the oil seal and prevents oil leakage at high speeds and when the temperature rises;

● Hydrodynamic knurlings and notches on the inner (working) surface. Dashed notches applied at some angle to the axis of the oil seal, preventing oil leakage at high shaft speeds. Notches can be made on the entire inner surface, or in the form of several rings on the working surface and working edges.

Oil seals are divided into two groups according to the direction of rotation of the shaft:

● For shafts with a constant direction of rotation;

● For shafts with reversible rotation.

Seals for various purposes differ in the type of knurling or notching on the working surface. In oil seals for shafts with a constant direction of rotation, the knurling is made in the form of hatching directed in one direction, so such parts come with "right" and "left" knurls (notches). In reversible oil seals, the notch is zigzag or more complex in shape.

Finally, there are two types of drive oil seals according to the degree of protection:

● Normal (standard);

● Cassette.

Conventional oil seals have the design described above. Cassette seals are made in the form of two rings inserted one into the other (the outer ring rests on the unit body and rests against the shaft, the inner ring rests on the outer and partially rests on the shaft) - this design withstands significant mechanical loads and provides better protection against the penetration of contaminants. Cassette seals are used on units operating in conditions of increased dust and pollution.

In conclusion, we note that in cars, tractors and other equipment, drive oil seals of various purposes are used: wheel shafts, gearbox shafts and gearboxes, fan drive shafts and others. But the bulk of the parts are located in the transmission, for which they got their name.

Cassette gland design

How to choose and replace the drive oil seal correctly

The drive oil seals are subjected to significant loads, which over time lead to wear, damage or complete destruction of the seal. If an oil leak occurs, the oil seal must be replaced, otherwise oil consumption will increase and the risk of contamination increases, which generally increases the intensity of wear of the parts of the unit. Also, oil seals need to be changed according to the development of the resource - the replacement period is usually indicated by the manufacturer of the unit.

Only those types and models of oil seals that were previously installed and recommended by the manufacturer of the mechanism (determined by the part number in the original catalog) should be used for replacement. In some cases, it is permissible to resort to replacements, but this should be done with caution and taking into account the characteristics of cuffs for various purposes. For example, the oil seals of the axle shafts of the drive axles must have a reversible notch (knurling), otherwise soon after their installation there will be an oil leak in certain driving modes or a constant leak due to improper functioning of the seal. On the other hand, it does not make sense to put a reversible cuff on the fan, since the shaft to be sealed always rotates in one direction.

Replacement of the drive oil seals must be carried out in accordance with the instructions for repair and maintenance of the vehicle. This work may require significant disassembly of the unit being repaired, so it is better to trust it to specialists. When replacing the seal yourself, you must strictly adhere to the recommendations given in the instructions, otherwise there is a high risk of damaging the part or installing it incorrectly. The recess of the old cuff can be performed with an ordinary screwdriver or other pointed object, but this must be done carefully so as not to damage the surface of the body and shaft. It is better to install a new seal using a special mandrel that ensures uniform sinking of the oil seal into the gland box. Before installation, the cuff is lubricated with lubricant. In cases where an oil seal with a bare or partially exposed reinforcing frame is used, it is necessary to treat the point of contact of the frame with the body of the unit with a sealant. After completing the work, it is necessary to add oil to the crankcase of the unit.

With the right choice and replacement of the drive oil seal, the unit will reliably perform its functions, its operation will not be disturbed by leakage and contamination of oil in any operating conditions.

Post time: Jul-13-2023