The transmission of multi-axle and all-wheel drive vehicles uses a mechanism for distributing torque between the drive axles - the center differential. Read all about this mechanism, its purpose, design, principle of operation, as well as repair and maintenance in the article.

What is a center differential?

Center differential - transmission unit of wheeled vehicles with two or more drive axles; A mechanism that divides the torque coming from the propeller shaft into two independent streams, which are then fed to the gearboxes of the drive axles.

In the process of movement of cars and wheeled vehicles with several driving axles, situations arise that require the rotation of the wheels of different axles at different speeds. For example, in all-wheel drive cars, the wheels of the front, intermediate (for multi-axle vehicles) and rear axles have unequal angular velocity when turning and maneuvering, when driving on roads with a slope and on uneven road surfaces, etc. If all the drive axles had a rigid connection, then in such situations some wheels would slide or, conversely, slip, which would significantly impair the efficiency of torque conversion and generally negatively affect the movement of traffic means. To prevent such problems, an additional mechanism is introduced into the transmission of cars and cars with several driving axles - a center differential.

The center differential performs several functions:

● Separation of the torque coming from the propeller shaft into two streams, each of which is supplied to the gearbox of one drive axle;

● Changing the torque supplied to each axle depending on the loads acting on the wheels and their angular velocities;

● Locking differentials - dividing the torque into two strictly equal streams to overcome difficult sections of the road (when driving on slippery roads or off-road).

This mechanism got its name from the Latin differentia - difference or difference. In the process of operation, the differential divides the incoming torque flow in two, and the moments in each of the flows can differ significantly from each other (up to the fact that the entire incoming flow flows to one axis, and nothing to the second axis), but the sum of the moments in them is always equal to the incoming torque (or almost equal, since part of the torque is lost in the differential itself due to frictional forces).

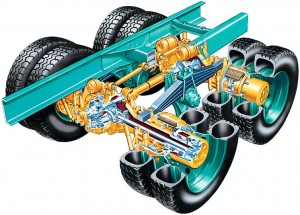

The center differential of three-axle vehicles is usually located on the intermediate axle

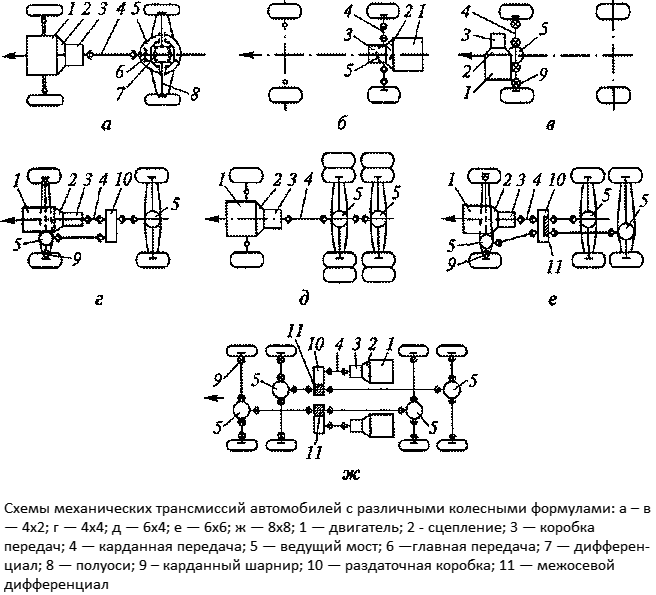

Center differentials are used in all cars and machines with two or more driving axles. However, the location of this mechanism may differ depending on the wheel formula and the characteristics of the vehicle's transmission:

● In the transfer case - used in cars 4×4, 6×6 (options are possible both for driving only the front axle and for driving all axles) and 8×8;

● In the intermediate drive axle – most commonly used in 6×4 vehicles, but also found on four-axle vehicles.

Center differentials, regardless of location, provide the possibility of normal operation of the vehicle in all road conditions. Malfunctions or depletion of the differential resource adversely affect the performance of the car, so they should be eliminated as soon as possible. But before repairing or completely replacing this mechanism, you need to understand its design and operation.

Types, device and principle of operation of the center differential

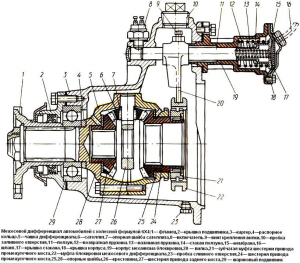

Various vehicles use center differentials built on the basis of planetary mechanisms. In general, the unit consists of a body (usually made up of two cups), inside which there is a cross with satellites (bevel gears) connected to two half-axle gears (drive axle gears). The body is connected by means of a flange to the propeller shaft, from which the entire mechanism receives rotation. The gears are connected by means of shafts to the drive gears of the main gears of their axles. All this design can be placed in its own crankcase, mounted on the crankcase of the intermediate drive axle, or in the housing of the transfer case.

The center differential functions as follows. With uniform movement of the car on a road with a flat and hard surface, the torque from the propeller shaft is transmitted to the differential housing and the crosspiece with satellites fixed in it. Since the satellites engage with the half-axle gears, both of them also come into rotation and transmit torque to their axles. If, for any reason, the wheels of one of the axles begin to slow down, the half-axle gear associated with this bridge slows down its rotation - the satellites begin to roll along this gear, which leads to an acceleration of the rotation of the second half-axle gear. As a result, the wheels of the second axle acquire an angular velocity increased relative to the wheels of the first axle - this compensates for the difference in axle loads.

The design of the center differential of the truck

Center differentials may have some design differences and features of operation. First of all, all differentials are divided into two groups according to the characteristics of the torque distribution between the two streams:

● Symmetrical - distribute the moment evenly between two streams;

● Asymmetrical - distribute the moment unevenly. This is achieved by using semi-axial gears with a different number of teeth.

At the same time, almost all center differentials have a locking mechanism, which ensures the forced operation of the unit in the mode of symmetrical torque distribution. This is necessary to overcome difficult sections of roads, when the wheels of one axle can break away from the road surface (when overcoming holes) or lose traction with it (for example, slip on ice or in mud). In such situations, all the torque is supplied to the wheels of this axle, and the wheels that have normal traction do not rotate at all - the car simply cannot continue to move. The locking mechanism forcibly distributes torque equally between the axles, preventing the wheels from rotating at different speeds - this allows you to overcome difficult road sections.

There are two types of blocking:

● Manual;

● Automatic.

In the first case, the differential is blocked by the driver using a special mechanism, in the second case, the unit is self-locking upon the occurrence of certain conditions, which are described below.

The manually controlled locking mechanism is usually made in the form of a toothed coupling, which is located on the teeth of one of the shafts, and can engage with the unit body (with one of its bowls). When moving, the clutch rigidly connects the shaft and the differential housing - in this case, these parts rotate at the same speed, and each of the axles receives half of the total torque. The control of the locking mechanism in trucks is most often pneumatically driven: the gear clutch moves with the help of a fork controlled by the rod of the pneumatic chamber built into the crankcase of the differential. Air is supplied to the chamber by a special crane controlled by a corresponding switch in the cab of the car. In SUVs and other equipment without a pneumatic system, the control of the locking mechanism can be mechanical (using a system of levers and cables) or electromechanical (using an electric motor).

Self-locking differentials may have locking mechanisms that monitor the torque difference or the difference in angular velocities of the drive axles of the drive axles. Viscous, friction or cam clutches, as well as additional planetary or worm mechanisms (in Torsen-type differentials) and various auxiliary elements can be used as such mechanisms. All these devices allow a certain torque difference on the bridges, above which they are blocked. We will not consider the device and operation of self-locking differentials here - today there are many implementations of these mechanisms, you can learn more about them in the relevant sources.

The design of the center differential of the truck

Issues of maintenance, repair and replacement of the center differential

The center differential experiences significant loads during the operation of the car, so over time its parts wear out and can be destroyed. In order to ensure the normal operation of the transmission, this unit must be regularly checked, maintained and repaired. Usually, during routine maintenance, the differential is disassembled and subjected to troubleshooting, all worn parts (gears with worn or crumbled teeth, oil seals, bearings, parts with cracks, etc.) are replaced with new ones. In case of serious damage, the mechanism changes completely.

To extend the life of the differential, it is necessary to regularly change the oil in it, clean the breathers, check the operation of the locking mechanism drive. All these works are carried out in accordance with the instructions for maintenance and repair of the vehicle.

With regular maintenance and proper operation of the center differential, the car will feel confident even in the most difficult road conditions.

Post time: Jul-14-2023