Each car has the ability to open side (door) windows, which is implemented using a special mechanism - a power window. Read about what a power window is and what functions it performs, what types it is, how it works and works in this article.

What is a power window

A power window is a mechanism for raising and lowering the glass of side (door) windows in vehicles, tractors, agricultural and other equipment.

The power window belongs to the auxiliary systems of the vehicle, it performs

several functions:

• Regulation of the position of door windows (their raising and lowering);

• Pressing the glass in the raised position in order to ensure the tightness of the door;

• Fixing the glass in any selected position;

• Partially - protection against unauthorized access to the car when the window is closed and ajar (due to the fixation of the glass).

The presence of a power window in the car allows you to adjust the microclimate in the cabin, ventilate, remove cigarette smoke, etc. Also, this simple device increases the convenience of using the car, allowing in some situations to avoid opening doors and leaving the car.

Types and features of power windows

Power windows are classified according to the type of drive and the design of the lifting mechanism.

According to the type of drive, power windows are:

• With manual (mechanical) drive;

• Electrically driven.

Manual windows are rarely installed on modern passenger cars, they are gradually being replaced by power windows (ESP). Manual windows are simpler in design and can be used even while the car is parked. ESPs are more convenient and comfortable, but they can only be operated when the ignition is on. Therefore, hand mechanisms are now widely used on tractors, special, agricultural and other equipment, as well as on trucks.

In turn, ESPs are divided into two types according to the algorithm of the control system:

• With direct (manual) control - only the power window drive motor control unit is provided, which replaces the mechanical window window handle;

• With electronic (automatic) control - an electronic control unit is provided, which significantly expands the capabilities of the power window, gives it various automatic functions.

Power windows can have a lifting mechanism of one of three types:

• Cable - the glass is driven using a steel cable, chain or belt;

• Lever - the drive is performed by a system of levers (one or two) by means of a gear train;

• Rack and pinion - the glass is driven by a movable carriage moving along a fixed rack and pinion.

Manual power windows can only have a cable and lever drive mechanism, ESPs are equipped with drive mechanisms of all types.

The power window is mounted in the inner cavity of the door, the manually operated mechanisms have a handle output on the inner panel of the door, in the ESP the control unit is located on the armrest of the door (there is also a central control unit on the dashboard or console).

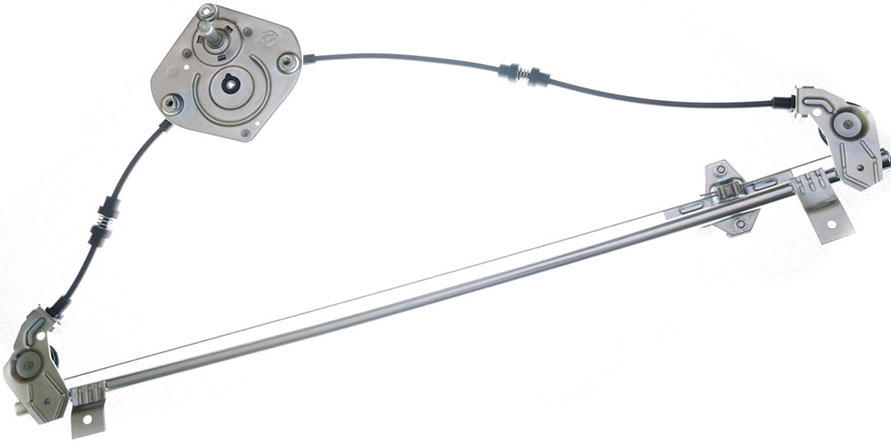

The design and principle of operation of the cable window regulator

In general, a cable window regulator consists of a drive mechanism, a flexible moving element, a glass bracket and a guide roller system.

The drive mechanism contains a gear train and an associated drive roller that ensures the movement of the cable. The gear train receives torque from the handle or electric motor, and converts it into translational motion of the flexible element. Also in the drive mechanism there is a spring locking mechanism that fixes the glass in the selected position.

• Longitudinal groove for oil supply to the hole (performed only on the liner located on the side of the channel - this is the lower main liner and the upper connecting rod liner);

• In collar thrust liners - side walls (collars) for fixing the bearing and limiting the axial movement of the crankshaft.

The liner is a multilayer structure, the basis of which is a steel plate with an anti-friction coating applied to its working surface. It is this coating that provides a reduction in friction and a long service life of the bearing, it is made of soft materials and, in turn, can also be multilayered. Due to its lower softness, the liner coating absorbs microscopic particles of crankshaft wear, prevents jamming of parts, scuffing, etc.

As a flexible element, a steel cable of small diameter is most often used, but it is also possible to use a chain and a timing belt. The cable bypasses the drive and guide rollers, the number of which can be two, four or more, the rollers are arranged so that the cable has one or two vertical (falling) branches. Brackets are mounted on these branches that hold the lower edge of the glass. For a reliable drive and to prevent slippage, the cable on the drive roller is laid in two turns.

There are two types of cable drive mechanism:

• With one working branch - the cable has only one vertical branch, on which the glass bracket is located;

• With two working branches - the cable bypasses several rollers and has two vertical branches on which the glass mounting brackets are located.

Cable windows often use rails in the form of a rack or tube, which run along the vertical branches of the cable and ensure the correct movement of the bracket. To protect against wear and corrosion, the cable on the supply branches is enclosed in a plastic sheath. And to compensate for the loosening of the cable tension, cable slack selection springs are provided, which are located at the ends of the cable, connecting it into a closed loop.

The cable window regulator works simply: the torque from the handle or from the electric motor is transmitted to the drive mechanism, converted by the gear train and transmitted to the drive roller. The cable located on the drive roller receives translational motion, and, depending on the direction of movement, raises or lowers the glass with the help of brackets. When the drive mechanism stops, the latch is activated (it can be just a spring or a more complex device), and the glass stops in the selected position.

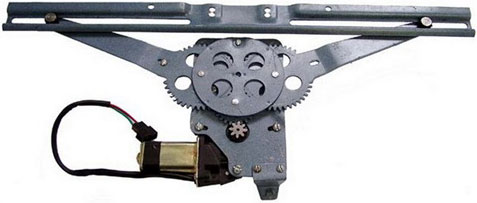

The design and principle of operation of the lever window regulator

The lever window regulator consists of a drive mechanism, a lever system and a backstage with a glass mounting bracket.

The drive mechanism consists of a drive gear, which receives torque from the handle or electric motor, and a gear sector. A lever is rigidly connected to the toothed sector, at the opposite end of which there is a roller of small diameter. The roller enters the slot of the rocker, which is connected to the bracket and rigidly fixed on the lower edge of the glass.

There are several types of lever window:

• With one lever;

• With a system of levers ("scissors"), one of which is the master, and one or two more are slaves;

• With two driving arms.

A power window with two driving arms is structurally similar to a mechanism with one lever, but it has two gear sectors connected to the drive gear and carrying levers. The mechanism with a lever system is more complex, it has only one drive lever, and a number of auxiliary levers that provide lifting and lowering of the glass with the support of the glass at two points. This type of mechanism avoids the uneven lifting and lowering of the glass inherent in mechanisms with two driving arms.

The lever window regulator works simply: the torque from the handle or electric motor is transmitted through the drive gear to the gear sector, and converted into the translational movement of the lever. With the opposite side, the lever pushes the backstage and the glass associated with it, the displacement of the lever is compensated by sliding its roller along the groove of the backstage. Fixing the glass in the selected position is carried out by a spring locking mechanism.

The design and principle of operation of the rack and pinion window regulator

The rack and pinion window regulator has an extremely simple device. The mechanism is based on a carriage that combines a drive gear, an electric motor and a glass mounting bracket. The carriage is located on a fixed vertical rack and pinion so that the drive gear engages with the teeth of the rack, and the rack also acts as a guide for the carriage.

The rack and pinion ESP works simply: the torque from the electric motor is fed to the drive gear, it begins to roll along the rack and pull the entire carriage behind it - this is how the glass rises or falls. When the carriage stops, the gear locks and the glass is fixed in the selected position.

Features of control and operation of power windows

In conclusion, a few words about the management of the ESP. On early models of devices, direct control was used, in which the handle was replaced by a button or buttons for controlling the electric motor. Such a system is simple, but has a lot of drawbacks, so it was replaced by an electronic control system with a lot of functions. For example, the glass can be raised and lowered by one short press of the control key, the system can automatically close the windows when arming the car, etc.

A modern window regulator is no longer just a mechanism, but a complex system with sensors, control and actuators, which makes the car more convenient and comfortable.

Post time: Aug-22-2023